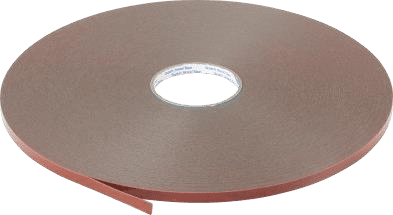

3M™ Acrylic Foam Tape GT7108

3M™ GT7108 is a gray, double-sided acrylic foam tape developed for secure attachment of automotive trims. Its viscoelastic core handles dynamic stresses from temperature changes while maintaining high adhesion across automotive paint systems.

3M™ GT7108 Features:

- Excellent conformability and bond-line appearance

- Resilient under thermal expansion and contraction

- High peel strength and environmental durability

3M™ GT7108 Applications:

- Attachment of appliqués, trim moldings, and step pads

- Deck lid trim and rocker panel moldings

- Thin or flexible automotive nameplates

About Prostech

Prostech Philippines is a one-stop solution provider for specialty materials and equipment across electronics manufacturing, from PCBA to final assembly. Our core material and equipment solutions include:

- PCB Assembly Materials

- Cleaning & Degreaser

- Circuit Board Protection

- Thermal Management Solutions

- EMI Shielding

- General Assembly Adhesives

- Elastomeric Materials

- Process Equipment: Potting & Coating Systems, UV/ Heat Curing, Plasma Treatment, Tape placement automation, and cleaning machines

Technical Added Value to customer

Prostech offers customized material and process equipment solutions with engineering support throughout R&D, production process optimization, and performance validation. Our in-house lab located in Alabang, Muntinlupa is equipped to conduct electronics material testing, application simulation, and adhesive validation, helping customers reduce the need for onsite trials and accelerate implementation.

International Supply Chain Advantage

Regional warehouse hubs across Vietnam, Singapore, Malaysia, and the Philippines ensure cross-border reliable supply. In Philippines PEZA-bonded warehouse located at Lima Industrial Park, Batangas enables Prostech to provide responsive, demand-based delivery and significantly shortens standard lead time for Philippines customers.

Need help selecting the right product or solution?

Typical Properties

|

90° Peel Strength |

|||

|

Test Conditions |

Substrate |

GT7108 (lbf/0.5") |

Peel Direction |

|

Initial (20 minutes after adhesion) |

Painted Panel |

3.10 |

|

|

Primed TPO Panel |

7.81 |

||

|

Normal (24 hours after adhesion) |

Painted Panel |

3.56 |

|

|

Primed TPO Panel |

9.22 |

||

|

Heat aging (10 days at 80°C/176°F ambient temperature) |

Painted Panel |

11.14 |

|

|

Primed TPO Panel |

11.16 |

||

|

Heat and Humidity Aging (10 days at 40°C/104°F and 100%RH) |

Painted Panel |

3.96 |

|

|

Primed TPO Panel |

7.84 |

||

|

80°C Static Shear (Time to failure in minutes — 10,000 minutes MAX) |

|||

|

Test Conditions |

Substrate |

GT7108 (minutes) |

250g Static Load |

|

1" x 1/2" tape sample laminated to the far end of a 3" x 1" paint sample. 3" x 1" anodized Al strip is then laminated to the other side of the test sample as indicated in the figure to the left. Tape sample tested in the 1" dimension direction. |

Painted Panel and PVC Panel |

10,000 |

|