Advantage of Low-temperature solder paste

Listed below are the four most notable benefits provided by LTS:

Enhanced output efficiency

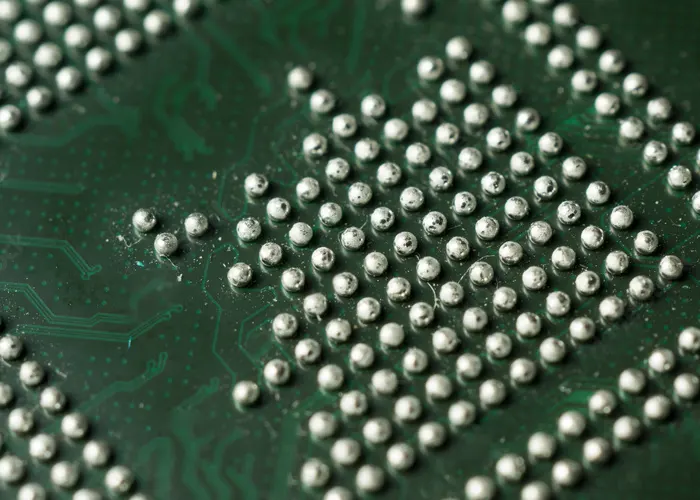

Compared to SAC305, LTS has a lower reflow temperature which leads to less deformation of PCBs and substrates, ultimately enhancing the BGA component packaging yield.

@Src: Alpha

Lowered thermal stability demand for PCBs and their components

By reducing the reflow temperature, it is no longer necessary for PCBs and components to endure temperatures as high as 240-250ºC. This also allows the product designer to select components and PCBs with lower thermal stability, resulting in a decrease in product cost.

Preservation of energy

Reducing the reflow temperature results in a decrease in the energy consumption of the oven, but the extent of the benefit depends on factors such as the oven’s thermal storage capacity, the type of product being produced, and the quantity being manufactured.

Eco-friendly manufacturing

The above image illustrates the significance of the green factor in electronics manufacturing. By lowering the energy consumption of the LTS process, it is possible to diminish the carbon footprint.

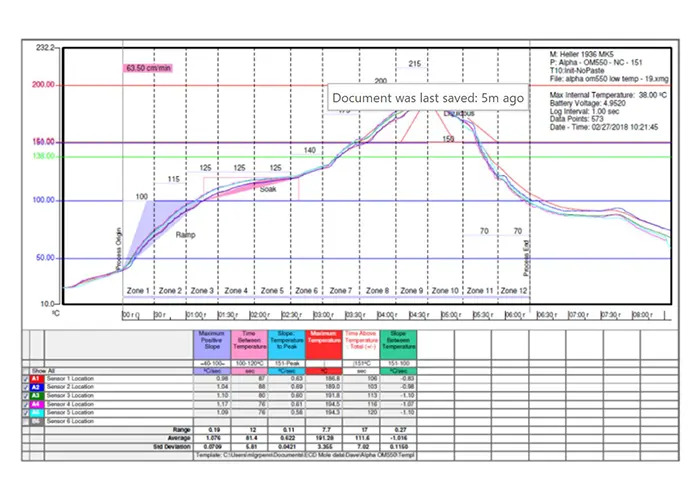

Reflow Profile of LTS

Disadvantages of Low-temperature solder paste

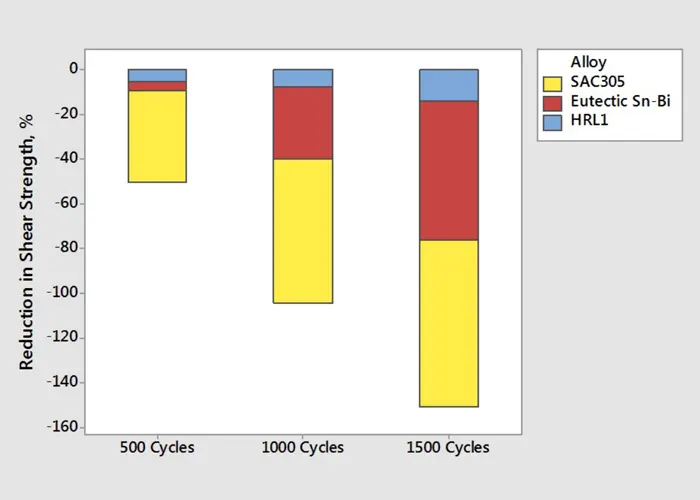

The SnBi alloy, particularly the Bi-rich phase present in its microstructure, is susceptible to brittle fractures at high strain rates. Compared to the SnAgCu alloy, the SnBi alloy exhibits inferior ductility. As a result, the drop test and mechanical shock test performances of SnBi solder joints are poorer. Specially:

Package Warp – Hot Tearing

Previously, BGA packages were designed to flatten out at temperatures over 210C, but this can result in hot tearing in the solder joint as the package remains warped during the reflow cycle. To address this issue, more solder paste can be used to compensate for the gap difference. Lower temperature alloys are less aggressive in wetting and can accommodate more solder per unit area without bridging. If these alloys are adopted on a large scale by the industry, packaging vendors may offer LTS versions of these packages to accommodate the shift.

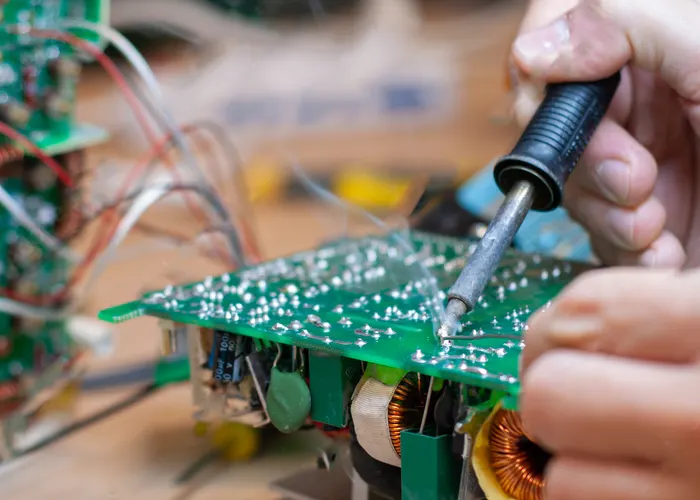

Rework

Due to its expansion when cooled, bismuth has the potential to create cracks in certain solder pots, such as those used in wave soldering.

In the term of solder wire, it is extremely scarce (with only one identified source that is not yet available for commercial use) and has a tendency to break easily.

Wide Liquidus / Solidus Range

It was necessary to cool the assembly very quickly to ensure that it was below 138C when it came out of the conveyor reflow oven.

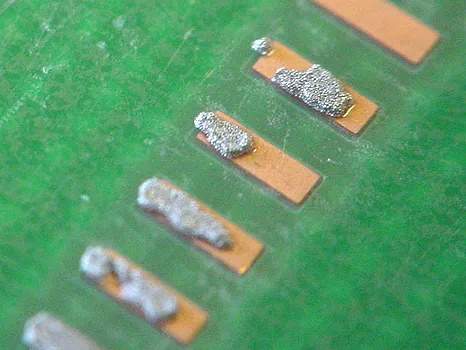

Flux Residue

There is a significant quantity of flux residue remaining after reflow. Over time, these solder pastes may develop to address this issue.

More Slump and Less Wetting

Based on our tests, there is a slightly higher slump (in both hot and cold conditions) compared to our controlled material. However, we attribute this to the maturity of the paste rather than the alloy itself. Unlike SAC-305, the alloy does not exhibit as strong of a wetting behavior, which may pose certain challenges in specific situations. Nevertheless, we still consider it to be satisfactory. In fact, in some cases, less wetting can even be advantageous, such as when using paste in hole.

However, these disadvantages will be solved if you can choose the right metal alloy for your low-temperature soldering process.

Contact us for more information & local support in Philippines: