What is Conformal Coating?

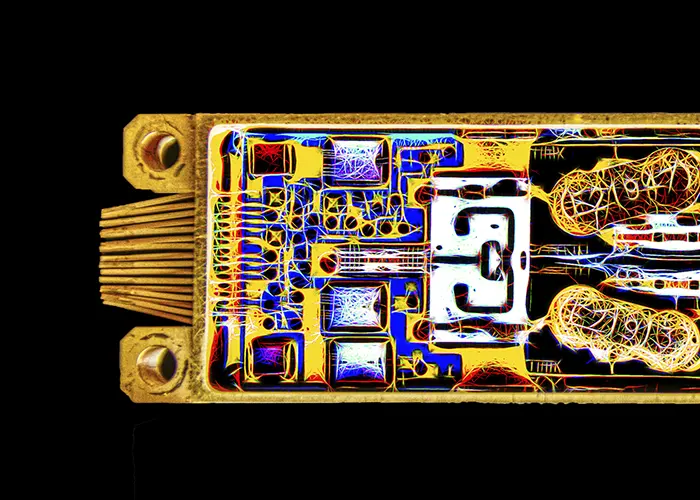

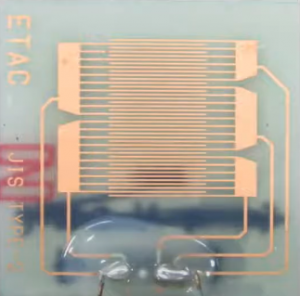

A conformal coating is a thin polymeric film applied to a printed circuit board (PCB) to protect the board and its components from the operating environment and corrosion. The film is typically applied at 25-250µm and ‘conforms’ to the shape of the board and its components, covering and protecting the PCB.

Conformal Coating can be applied in a number of ways, including brushing, spraying, dispensing, and dip coating. See more

Furthermore, a number of materials can be used as a conformal coating, such as acrylics, silicones, urethanes, epoxies, and perylene. Initially, the material is coated onto the PCB in liquid form, then cure according to different mechanisms. Other specialist types of Conformal Coatings such as Parylene are applied differently. They are not liquid bases and are applied in a chemical vapor deposition process. Each has its own characteristics, making them preferred for certain environments and manufacturing scenarios. Most circuit board assembly firms coat assemblies with a layer of transparent conformal coating, which is lighter and easier to inspect. However, the colored coating can be used to secure the PCB design. Conformal Coating can be applied in many industries such as electronics (handheld devices-pads, smartphones, speakers), automotive, military, air transportation, and medical devices.

Benefits and Purposes of Conformal Coating

The main purposes of Conformal Coating include:

Improving electrical properties of the PCB

|

|

Insulation is a prerequisite for coating. The electronic circuit boards are more and more compact but must perform complex functions, resulting in high-density electrical interconnect packaging. A layer of Conformal Coating provides the PCB with insulation while increasing dielectric strength between the connections and components. |

Protecting the PCB from the harsh operating environment

|

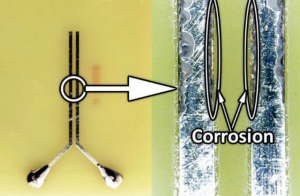

With the strong growth of technology, PCBs are used in most industries, which means that sensitive PCBs are more and more exposed to hazardous environments such as moisture, dust and debris, corrosive agents, chemical substances, temperature extremes, etc,…These factors cause serious damage to the circuit board. Conformal Coating prevents those agents from harming the PCB by a layer of polymeric material. This material is resistant to chemicals, prevent contaminants as well as dust and debris from entering the PCB, and damages solder joint and components. It also prevents moisture from causing corrosion. Conformal Coating can provide resistance to environmental exposure, but they are not fully water-proof. |

Contributing to heat dissipation

Temperature is the most influential factor in the failure of electronic components, so the PCBs must have effective thermal management. Organic coatings are seldom used for the primary purpose of conducting heat. Unfilled polymers and polymer coatings have low thermal conductivities. Filler can be used to increase thermal conductivities of the coating, but also decrease its insulation. Therefore, that method of increasing thermal conductivity is only used in some special cases. Normally, Conformal Coating is applied as thin as possible for easier heat transfer, since thermal conduction is inversely proportional to thickness.

Advantages and Disadvantages of Conformal Coating

Advantages

Among the electronic circuit boards protection solutions such as potting/encapsulating and low-pressure molding, conformal coating is different in its ability to protect the PCB with only a thin layer. A thin layer has many benefits for the operation of a printed circuit board in addition to good protection from chemical agents, dirt and debris, moisture,….

Firstly, thanks to the thinness of the conformal coating, it causes a minimum increase in the overall volume and size of the PCB. That is also useful for designs that require compact and tight, precise dimensions.

At the same time, this thin layer also allows heat to be transferred from the PCB to the outside quickly, minimizing the risk of component failure or corrosion due to high temperatures. It’s also much easier to inspect and repair the PCB with conformal coating than with potting/encapsulant as well as low-pressure molding. We can easily observe the components on PCB through a transparent film.

However, when necessary, the colored coating is used to secure the PCB’s design. A coating applies relatively little stress upon the components, this is a particular advantage where a component has thin pins or legs.

Another advantage of Conformal Coating is that it provides a wide range of methods to apply. The manufacturer can choose the suitable method that fit the production scale and PCB’s requirements from manual brushing to automatic dispensing. The flexible processes can be easily done by the automated system. Initial investment costs will make the later production process efficient and economical.

Disadvantages

Besides the above advantages, there are some disadvantages of conformal coating that need to be considered in order to have a reliable coating.

Although Conformal coating can protect the PCB from moisture, it is semi-permeable and not waterproof. Therefore, it is rarely used in environments exposed to a lot of moisture and water.

Also, Conformal Contains VOCs within the solvents, though these are becoming less and less abundant.

Conformal coating is not effective to protect the PCB from vibration and impact because of its thinness. For applications subject to frequent shocks and vibrations, potting/encapsulating and low-pressure molding are preferred. While can be done automatically, the process of Conformal Coating is quite long and complicated, requires meticulousness and precision.

Contact us for more consultant from experts in the Conformal Coating field:

Email: gluexpert@prostech.ph

Hotline: (+84) 984 695 398