What is UV Adhesive?

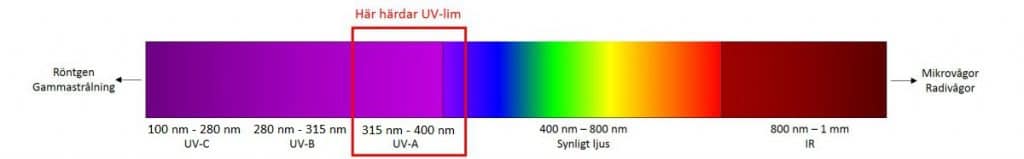

UV curing adhesive or often called light curing, photo-curing adhesives, are adhesives that cure when illuminated with light within a specific wavelength, usually of UV-A or “blue-light” approximately 365 nm to 405 nm. This is the main reason why the term UV curing adhesive has been developed.

A light-curing adhesive is not really a type of adhesive but a curing mechanism.

Our Product Range:

♦ UV Adhesive

♦ UV Conformal Coating

♦ UV Temporary Maskant

♦ UV FIP/ CIP Gasket

When/ Which applications are UV Adhesive used?

Light curing adhesives are always the first and foremost choices for fast cure speed desired applications. Often, a full cure is achieved in seconds and that is also the main advantage of this type of adhesive.

Probably, two material substrates are being bonded together. This means that at least one of these materials must transmit the light so that it can reach the bond line.

Referring to the possibly bonding materials, UV adhesives are ideal for many applications in which glass or plastic which are able to convey UV or visible light is bonded to itself or metals and other substrates.

Markets:

♦ UV adhesive for Electronics

♦ UV adhesive for Medical

♦ UV adhesive for Home Appliance

♦ UV adhesive for Aerospace

♦ UV adhesive for Automotive

UV Adhesive Characteristics

♦ High Strength Bonds

♦ Cure Only When Exposed to Light – permits alignment of parts prior to bonding.

♦ Select a Cure Speed – double production speed by simply adding another lamp to the line.

♦ Solvent-free – Non-flammable – increase safety

♦ Single Part Product – No mixing required

♦ 100% solids – No waste.

♦ Save energy – UV lamps require less electricity than heat cure ovens for epoxies

♦ Space savings – UV lamps require less space than heat cure oven tunnels

♦ Appearance – UV glue is available in clear colorless formulations

♦ Technical Support – application specialists available for assistance with joint design, adhesive selection, and production process.

How does light-curing adhesive work?

We usually heard that UV Glue cure quickly when exposed to the light of the appropriate wavelength and intensity. So exactly how this process carries out?

Every UV Adhesive have in common is that the adhesive formulations contain monomers and oligomers (building blocks for the adhesive) and some type of photo-initiator (a small molecule that initiates the curing reaction with the help of light).

When the photoinitiator absorbs light of a certain wavelength and intensity, it starts a polymerization reaction – the adhesive cures. As s result, it is important to make sure that the adhesive matches the UV lamp meant to be used: Intensity, the wavelength of light, and the configuration of the UV light system are all important aspects to consider.

So long as the adhesive bond is illuminated by the light, the reaction carries on. However, if the light is removed too early, the reaction pauses. Consequently, it is important to cure a light-curing adhesive the correct amount of time. Too short curing time leads to incomplete cure (which is why a safety factor is incorporated) and too long cure time can cause degradation of the adhesive. Degradation will weaken the bond and cause discoloration. Exposing the adhesive to 2-3 times the recommended dose is usually ok.

For more information about our product, please contact:

Email: gluexpert@prostech.ph

Hotline: (+84) 984 696 398