- Super Glue Dispensing Challenges

- Recommended dispensing systems for cyanoacrylates

- Manual hand-lever valve

- Benchtop system with an air-powered fluid dispenser

- Benchtop system with a dispense valve, valve stand, and valve controller

- Semi-automated System with a Tabletop Dispensing Robot, Dispense Valve, and Valve Controller

- Semi-automated System with a Tabletop Dispensing Robot, Jet Valve, and Valve Controller

- Fully automated System with parts that advance on a Production Line

Cyanoacrylate adhesives, also known as CAs (or cyanos, super glue, rapidly curing adhesive), are highly effective at bonding many types of materials together in assembly processes. This makes them an ideal choice for assembling products in a variety of industries, including automotive, electronics, and consumer goods. Though beneficial, these moisture-cure adhesives can be a challenge, especially when your assembly process requires precise, repeatable dispensing.

Let’s find out how to minimize material waste by more than 60% while also minimizing operator exposure to the adhesive. Speed your production processes while producing higher quality parts with less downtime.

Super Glue Dispensing Challenges

| The main challenge when dispensing cyanoacrylates is keeping unwanted moisture out. Any moisture that contacts the CA will start the bonding reaction prematurely. This can cause costly rework and rejects, in addition to slowing production. |  |

Unfortunately, some of the advantages of CAs contribute to its dispensing challenges, including:

- Correct placement — Due to its fast-setting nature, a CA must be applied accurately the first time, since even small adjustments after curing are generally not possible.

- Precise deposits — The strongest bond is created with a minimal amount of cyanoacrylate. This presents a challenge for operators because it’s not easy to apply thin deposits consistently. Since most cyanos are low viscosity, this can be particularly challenging because thin fluids are often prone to dripping.

- Migration — This occurs when CAs seep beyond the desired deposit location, creating chalky, white filaments that can impair part quality. Preventing migration is a major dispensing challenge and is especially tricky with low viscosity cyanos.

- Safety — Since CAs can adhere to the skin, skin contact should be avoided. This is a safety concern for operators. Dispensing systems must safely contain the fluid and reduce the amount of handling.

- Cost — Because many CAs are expensive, inconsistent dispensing can lead to costly material waste and part rejection. This is another reason to consider using precision dispensing solutions that can reduce fluid waste by more than 60%.

Recommended dispensing systems for cyanoacrylates

Recommended dispensing systems for cyanoacrylates include hand-lever valves, benchtop dispensers, semi-automated dispense valves, and automated dispensing robots. These systems provide controlled, repeatable dispensing results. Some reduce material use by as much as 60% and virtually eliminate rejects.

Manual hand-lever valve

When using a hand-lever valve, the operator determines the amount of cyanoacrylate needed by looking at the deposit size as it is dispensed. Material is fed to the valve directly from a 1-liter tank containing a 1-pound bottle of CA. The amount of adhesive dispensed is not metered by the system. The material is pumped with consistent pressure to deliver uniform deposits. Handheld valves are best for low-volume production and applications that require larger deposits or stripes.

Benchtop system with an air-powered fluid dispenser

In this system, an operator holds a syringe barrel and guides the dispense tip to the correct location, then presses the foot pedal or finger switch to release the fluid. This is a much more controlled dispensing method than squeeze bottles or hand-lever valves. The system is best for low- to medium-volume production and applications that require smaller, more precise deposits.

Benchtop system with a dispense valve, valve stand, and valve controller

In this system, an operator places the part or workpiece under the valve, which is fixed to a valve stand. The operator actuates the dispense valve, which is connected to the valve controller. This option is ideal for medium-volume production processes.

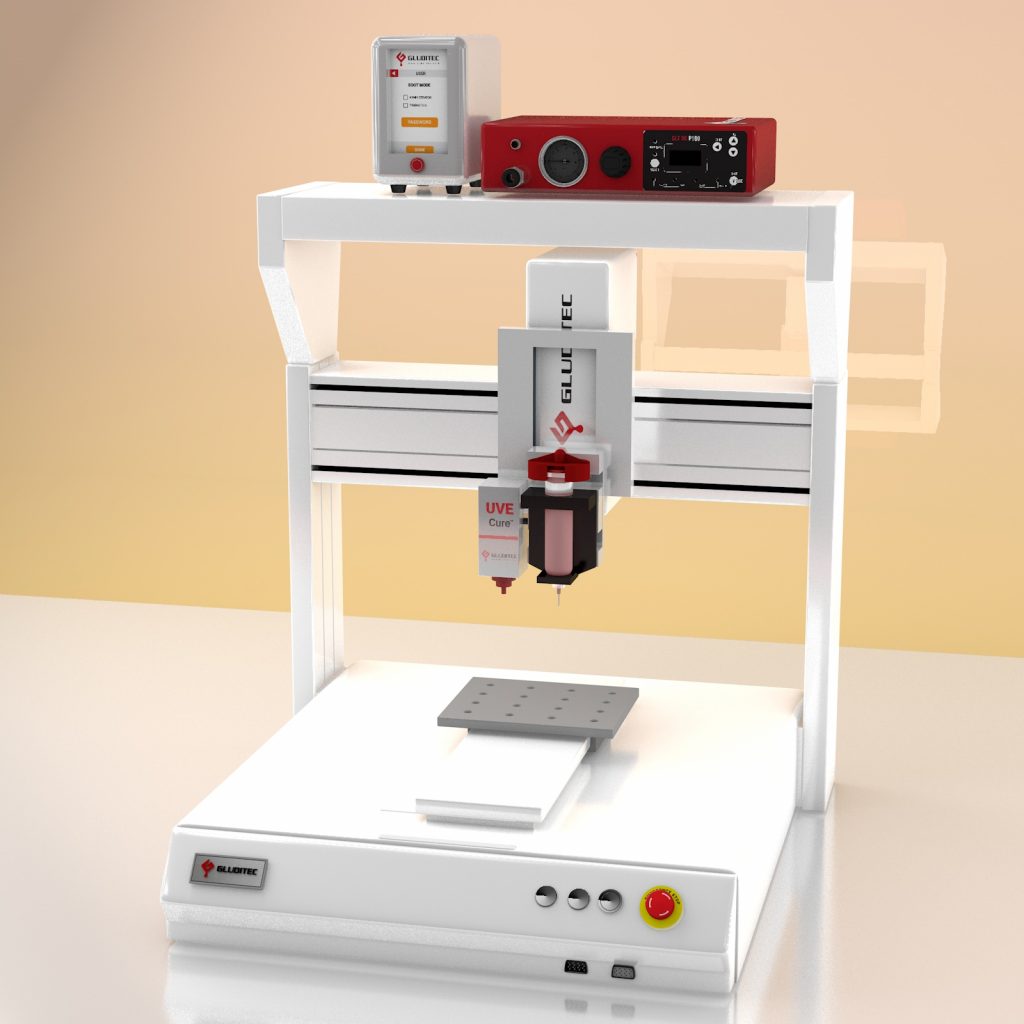

Semi-automated System with a Tabletop Dispensing Robot, Dispense Valve, and Valve Controller

In this system, the operator places a batch of parts on a fixture plate and presses the run button. The dispense valve is mounted to the dispensing robot. The valve controller is the interface between the robot actuation signal and the valve. With this system, the valve dispenses a controlled amount of CA in a pre-programmed pattern onto the workpiece. A dispensing robot can dispense CAs in complex patterns. This is the best option for higher volume production or applications that require extremely precise, repeatable deposit placement.

Semi-automated System with a Tabletop Dispensing Robot, Jet Valve, and Valve Controller

As noted above, the operator places parts on a fixture plate and presses the run button. The valve is mounted to the robot and the controller actuates the valve. With jet valves there is no contact between the dispense nozzle and the workpiece. This allows for faster deposit placement on tough-to-reach or uneven surfaces and reduces the risk of part damage and contamination. Jet valves also dispense very small amounts at fast speeds with exceptional repeatability — providing even greater process control.

Fully automated System with parts that advance on a Production Line

In this system, parts placed on a conveyor or rotary table are detected by sensors and automatically receive a deposit of CA from the dispensing valve. The valve may be mounted on the line and controlled by a valve controller or PLC. It may also be mounted on an automated dispensing robot, which is programmed and controlled via a personal computer.

The importance of properly handling cyanoacrylates in a dispensing process cannot be over-emphasized. If you would like to experience greater productivity and other benefits from more controlled CA dispensing, please connect us for free consultant.

Hotline: (+84) 984 695 398

Email: gluexpert@prostech.ph