LED-Optimized Medical Adhesive for Plastics and Metals

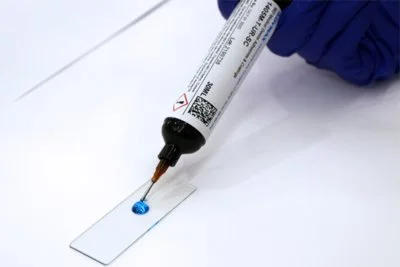

MD® 1405-M-UR-SC needle bonding adhesive is LED curable at either 385 nm or 405 nm wavelength light for fast bonding of multiple substrates typically used in syringe and medical device manufacturing. Its low viscosity makes it ideal for tight tolerance applications.

The product features Encompass® technology which incorporates Dymax patented See-Cure color change and Ultra-Red® fluorescing technologies into one light-curable product. See-Cure technology enables easy visual confirmation of material placement onto substrates and verification of full adhesive cure. Ultra-Red technology provides bright red fluorescence under low-intensity black light (365 nm) and assists with quality inspection of the bond line.

Bondable substrates of MD® 1405-M-UR-SC include stainless steel, PC, PMMA, FR4, and also ABS. Typical applications include assembling dialyzers, winged infusion sets, and point-of-care devices, as well as needle/syringe joining.

Dymax MD® Medical Device adhesives are solvent-free and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax light-curing spot lamps, focused beam lamps, flood lamps, or conveyor systems they deliver optimum speed and performance for medical device assembly. Dymax lamps offer the optimum balance of UV and visible light for the fastest, deepest cures.

| Property | Values |

| Viscosity (nominal) | 150 cP |

| Cured durometer hardness | D70 |

| Cured elongation at break | 150% |

| Recommended substrates | Stainless Steel; ABS; PC; PCTG; PEI; PETG; PS; SAN |