Why Thermal Management is essential in EVs Motor?

Motor designers have battled heat in motor designs for years. Thermal losses in electric machines rob motion systems of power and degrade efficiency. Excess heat can reduce the reliability of motors and shorten their lifetimes. Meanwhile, electrification in all transportation sectors is driving requirements for motors with ever-higher power densities. Good thermal management in electric machines and their power electronic drives can minimize losses, particularly copper (I2 R) losses, and yield improved performance, reliability, and efficiency.

Type of Thermally Conductive Materials in Potting Application

Historically, varnishing of the rotor and stator windings was common to achieve a minimum level of insulation, such varnishes were solvent-based and contained a high percentage of Volatile Organic Compounds (VOCs). However, with increasing environmental awareness, legislation restricts the use of VOCs due to their emissions into the environment. Such varnishes do not fulfill the higher requirements of e-motors in the automotive industry where the challenges are higher power density caused by size reduction, increased power output, reliability, and endurance in harsh environments.

This means there are now even more reasons to use Encapsulation Resins and they deliver plenty of value-added benefits:

All-round Protection – Acting as a barrier to the external environment, encapsulation resins provide physical, chemical, and thermal protection. They can physically dampen the impact of shock vibrations or dampen noise produced by the motor. Some encapsulation resins also benefit from flame retardant properties.

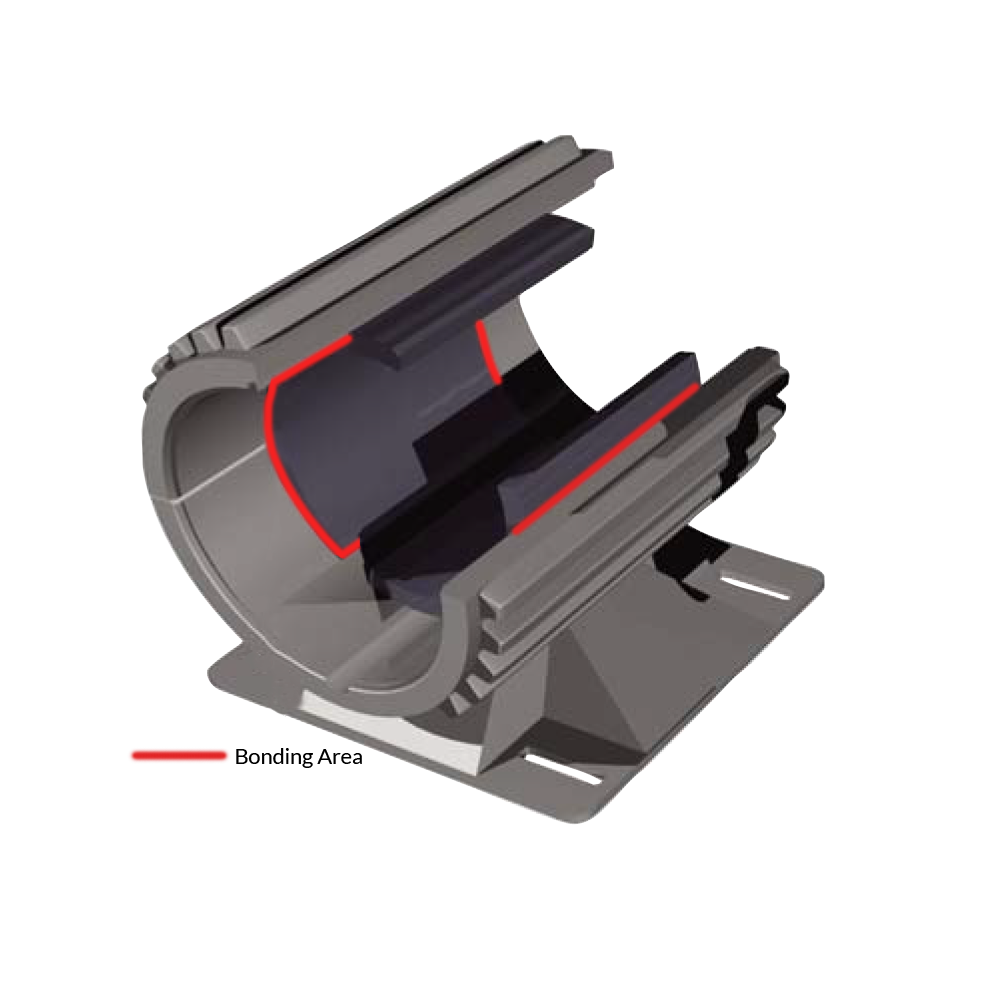

Electrical Insulation – Air and voids can create partial discharges between ground and primary insulation. Encapsulation resins can be used to completely fill all internal spaces, often helped by vacuum potting methods to fill all the tiny spaces to guarantee electrical insulation.

Thermal Dissipation – Some encapsulation resins have high thermal conductivity and are extremely effective at dissipating heat away from hot spots and improving the overall thermal endurance.

Noise, Vibration and Harshness (NVH) – Although e-motors are quieter than traditional internal combustion engines and have fewer moving parts, electric vehicles create higher frequency noise that can be annoying over a long period of time. Resins are used to handle the NVH and add perceived value for any vehicle owner.

Type of Potting & Encapsulating Resin for EVs Motor

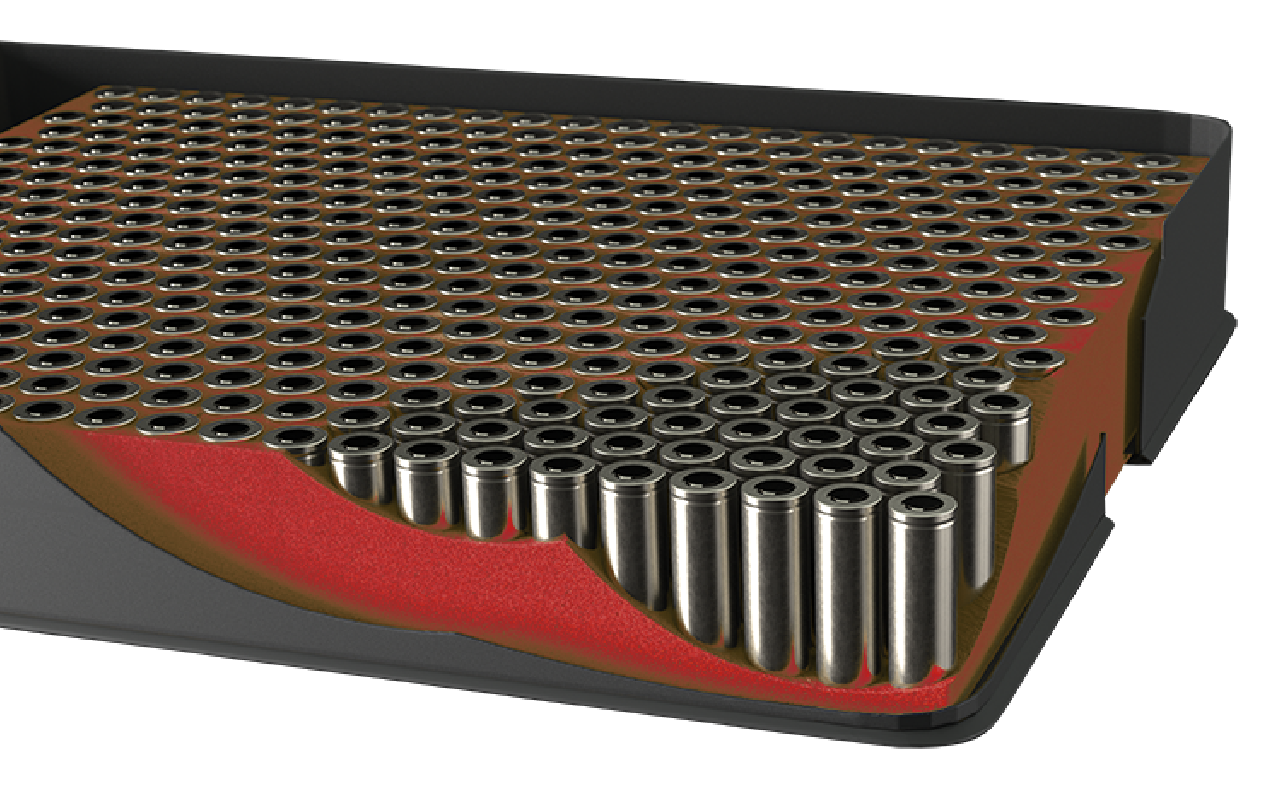

Unlike aerospace applications, where two or three layers of redundancy may be built into systems, automotive designs typically must work the first time, every time, throughout the life of the product. We have expansive resin solutions that improve performance and reliability. By way of example, resin solutions for EV applications would include Epoxy Resin, which is frequently chosen as the resin material to electrically insulate the coil ends of stator windings found in electric vehicles. This resin is highly resistant to immersion in chemicals found in electric and hybrid vehicles, including cooling fluids, and has extremely wide operating temperature ranges. Its low viscosity also allows for easy potting of all the tiny spaces between the winding coils. However, one of the biggest disadvantages of epoxy resin is the lower thermally conductive index, compared to the new silicone potting compound.

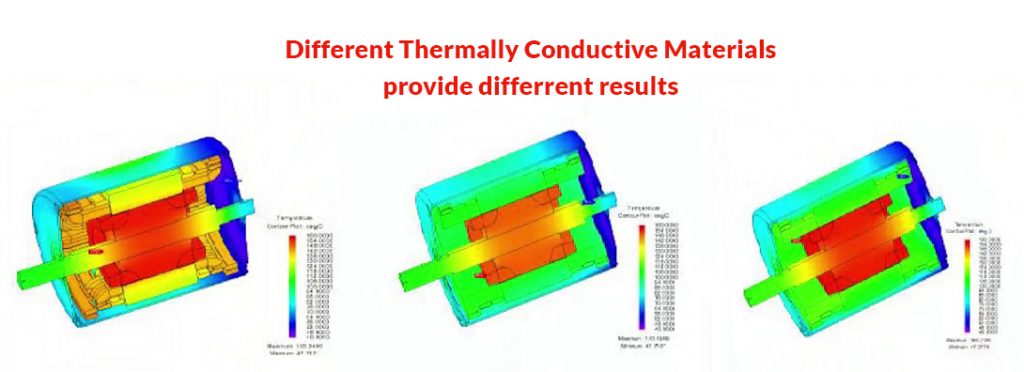

EVs produce vast amounts of heat during operation and whilst charging. To achieve prolonged e-motor life and higher efficiency, Silicone Potting Compound is a highly thermally conductive resin with low viscosity, ideally suited for e-motor coil potting within an electric vehicle. In comparing the effects of various impregnation materials, the hot spot temperatures of the windings were measured under various coolant flow rates and current levels for each of the potted motors. The hot spot temperatures of the motor impregnated with some type of silicone potting compounds were generally 40°C to 45°C cooler than the varnish only motor, and about 12°C to 15°C cooler than the epoxy-potted motor.

See more about Potting Material and Vacuum Potting System here

Future developing trend of requirements for EVs

There is clearly a change in customer requirements in line with the trend for EV’s, such as improved range, faster charging times, and the wider availability of charging stations. With each new iteration, the next generation of design, typically means components get smaller in size, and their power output increases. This normally means that the heat generated from higher density power output components increases. In turn, both short- and long-term operating temperatures of resins need to increase to perform sufficiently. Since resins are used in many areas on a vehicle, from sensors and displays to the motors themselves, lots of development by PROSTECH is focused on pushing the limits of thermal performance and thermal conductivity to remain as the solutions provider of choice for the ever-changing automotive industry.

E-mobility is an evolving market, where the various performance criteria for vehicle components are constantly changing to keep up with the latest developments in technology. Encapsulation resins capable of dissipating heat away from hard-working components clearly add value to the automotive electronics industry. With multiple research and development facilities, PROSTECH is well-positioned to quickly respond to these market changes. Our Technical Support Engineers are on hand to support design engineers select the best encapsulation resin for their unique applications. I hope this has been of interest to those of you involved in EV and helps make life a bit easier for those who are responsible for making the decisions on protecting components and circuitry.

Hotline: (+84) 984 695 398

Email: gluexpert@prostech.ph