What do we mean by good electrical stability?

Good electrical stability means that there is a very little ionic movement within the epoxy mold compounds when semiconductor devices are under reverse bias at elevated temperatures.

Epoxy mold compounds that are considered to have excellent electrical stability:

- Have low ionic conductivity

- Have a low and stable permittivity at temperatures up to 200°C.

- Have a high dielectric strength.

- Have a stable dielectric constant over a frequency range from 1 kHz up to 1.8 GHz.

What causes poor electrical stability in mold compounds?

There are two main causes of poor electrical stability in EMCs:

- The ingredients used have high ionic content.

- The epoxy resin and hardener combination have high ionic conductivity.

EMC subcomponents have high ionic content

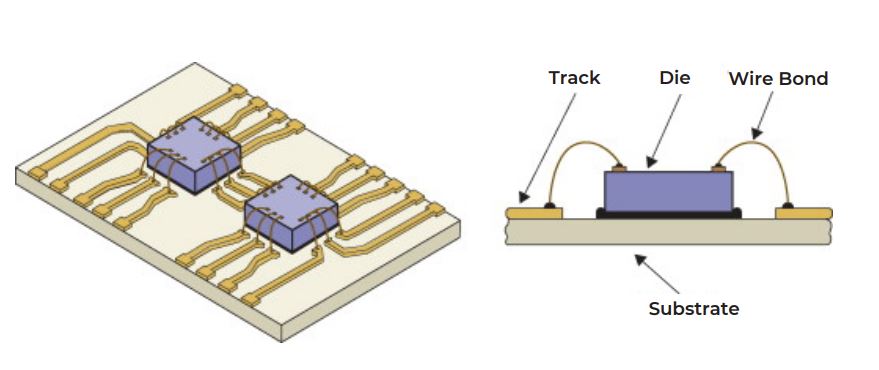

Epoxy molding compounds are made up of many components including epoxy resins, curing agents, catalysts, fillers, pigments, and additives. Each of these ingredients can contain ions in the form of chlorine (Cl-), Sodium (Na+), Fluorine (F-), and Potassium (K+). There are elements other than these that have ions, but these are the ions most frequently present and in the highest quantities – therefore are of the greatest interest. As you can see next to the elements listed, Chlorine and Fluorine both have negative (-) ions, and Sodium and Potassium both have positive (+) ions.

Of these four elements, the biggest culprits are Chlorine (Cl-) and Sodium (Na+). If the total ionic content is too high, or the ionic content of each of the Chlorine or Sodium is too high, then the risk of gate current leakage and device malfunction increases. In all semiconductor applications, it is prudent to have the total extractable ionic content to be less than 80ppm and the extractable content of each element to be below 20ppm. In high-power semiconductor applications, which operate at higher voltages and higher temperatures, it is better to have the total ionics to be below 20ppm, and of each element to be below 5ppm. As application temperature and power increase, the lower the ionic content the better.

Epoxy resin/ hardener combination has a high ionic conductivity

When exposed to the electric field caused by the DC voltage applied, these ions have a tendency to move. If they move too much, agate current leakage occurs and gradually increases which ultimately leads to the device malfunction.

Different combinations of epoxy resin and hardener will provide different ionic conductivities of the base epoxy. Specifically, as illustrated in Figure 1 below, a standard epoxy cresol novolac resin with a standard phenolic resin might have a low permittivity at lower temperatures, but quickly elevate at higher temperatures leading to gate current leakage failures for power semiconductor devices.

Formulating electrically stable Molding Compounds

Epoxy mold compound formulators can develop materials that will pass the HTRB test by developing EMCs that:

- Have low ionic content, low ionic content, and low ionic mobility

- Use ion trappers

- Have low permittivity

- Use epoxy resin & hardener combinations that have the lowest ionic content and mobility

For more advice on Epoxy Molding Compounds, contact us through: