Ever wonder how that bag of chips stays sealed? Or how your yogurt stays fresh in its container? The secret lies in a hidden hero – adhesives! From the colorful labels adorning your juice box to the resealable pouch on your bag of nuts, adhesives play a hidden but crucial role in our everyday lives. Let’s find out what food-grade adhesive is and how we can apply it with appropriate techniques!

1. Food-grade safety legislations

Currently, food safety is a top priority so how can we be sure these adhesives aren’t a hidden risk? The answer lies in strict regulations like FDA 175.105 or EU Food Contact Regulations No 10/2011.

- FDA 175.105 is a regulation set by the US Food and Drug Administration (FDA) that outlines the requirements for adhesives used in indirect contact with food. Indirect adhesives are those used to bond parts of food packaging or attach packaging to food itself.

- The EU Food Contact Regulation (EC) No 10/2011, also known as the Plastic Materials and Articles Regulation, is a key piece of legislation in the European Union (EU) that governs the safety of materials that come into contact with food.

These regulations exist to ensure these adhesives aren’t made with harmful components or migrate into food at levels that could pose health risks.

2. Feature of food-grade adhesives

Food-grade adhesives are required for kitchen goods, packaging applications and production line equipment. They are also found on dry food packaging, paper wrapping that encases food or seal cartons. Food-safe adhesives that are FDA/EU-approved are needed to bond mesh gauze on filters, sleeves and strainers; seal parts on dispensing equipment like ice cream or beverage dispensers; bond ceramics, handles onto kitchen knives and coffee pots; add labels and packaging and seal production line conveyors and equipment.

Food safety depends on all components which contribute to the construction of final packaging. Adhesive, although a small component, is key for productivity on high-speed machines, enhances aesthetics, provides bond and withstands wide range of temperatures.

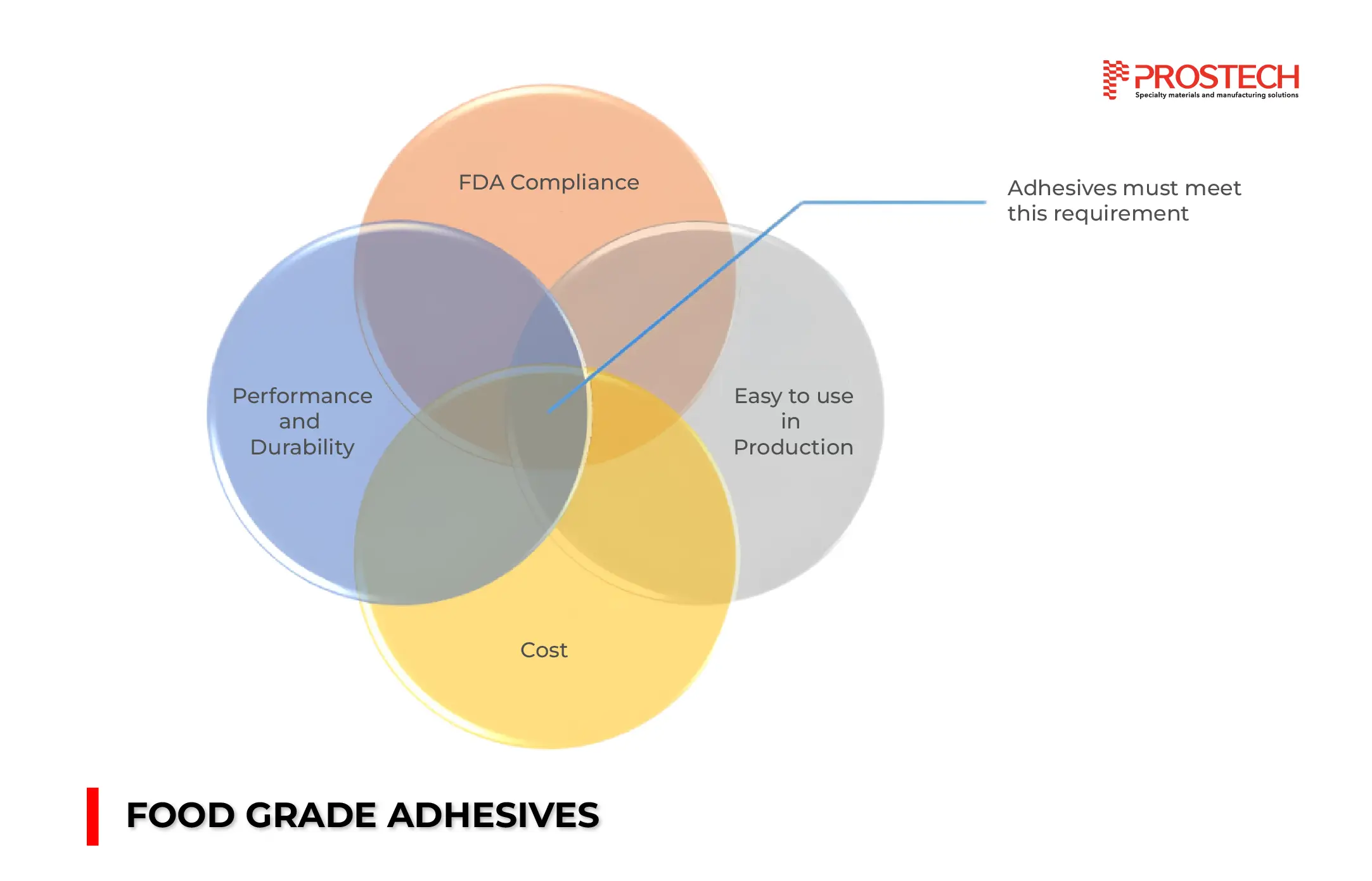

Adhesive needs not only to meet specific functional requirements such as adhesion strength, moisture resistance, heat resistance or flexibility depending on the application but also safety because adhesives used in food packaging can sometimes indirectly encounter foods.

That’s why manufacturing food-grade adhesives is a complex process with strict regulations to ensure the safety of the final product. In addition, the raw materials used need to be of high purity to minimize any potential migration of harmful substances into the food.

In conclusion, Food-grade adhesives need to meet a number of critical properties to ensure the safety and integrity of food products:

- Non-toxic and food-safe

- FDA/EU compliance (or equivalent)

- Specific functional requirements: Adhesion, heat and moisture resistance, chemical resistance…

3. Application

Food-grade adhesives play a vital role throughout the entire process, from packaging to processing equipment.

- Food packaging: Sealing cartons and boxes, Labeling, Wrapping and bags…

- Food Processing Equipment: Sealing filter and strainers, attaching components, …

- Kitchen goods: Bonding handles, assembling certain cookware, …

- General food contact application

To FIND OUT MORE about Epoxy Adhesives Application in Food and Beverage Manufacture, you can dive into this article: Epoxies for food & drink applications

4. Recommendation solution

The ever-evolving food and beverage industry demands innovative solutions that meet stringent food safety regulations. Prostech rises to the challenge, delivering cutting-edge adhesive solutions tailored to our customer’s specific needs. From labeling, packaging, kitchen goods to equipment and filters, we offer a comprehensive range of products:

|

|

Prostech ensures optimal performance and reliability in these critical materials solutions through advanced technology and meticulous attention to detail. With a focus on improving efficiency and improving the quality of life, Prostech’s food-grade safety solutions will bring you great experiences when using our products.

—————————————–

For more information, contact us to talk with our glue experts: