Product Introduction

The GLUDITEC GSP-300 glue supply system is designed for precise and consistent dispensing of adhesives from 300cc and 330cc packaging. Utilizing cylinder pressure and a screw pump’s self-suction mechanism, it ensures a constant material flow. Coupled with a timing-controlled valve, this system achieves accurate dispensing volume and speed, making it ideal for high-viscosity adhesives in automated production environments.

GLUDITEC GSP-300 Features:

- Compatible with 300cc/330cc silicone and sausage-type glue packaging for accurate fixed-weight dispensing.

- Handles high-viscosity adhesives ranging from 10,000 to 1,000,000 cps.

- Eliminates glue breakage and instability caused by pneumatic pressure pump pulsing.

- Equipped with a touchscreen controller, low liquid level alarm, and adjustable glue volume via speed setting.

- High dispensing precision within ±3%, with a range from 0.03g to 5g/s.

- Durable and cost-effective design with minimal part replacement needs.

- Compact and easy to integrate into automated systems.

GLUDITEC GSP-300 Applications:

- Fixed-weight dispensing from 300cc/330cc adhesive containers.

- Automated assembly lines utilizing high-viscosity adhesives.

- Precision glue dosing in electronics, automotive, and medical industries.

- Smart manufacturing environments requiring consistent output with minimal waste.

About Prostech

Prostech Philippines is a one-stop solution provider for specialty materials and equipment across electronics manufacturing, from PCBA to final assembly. Our core material and equipment solutions include:

- PCB Assembly Materials

- Cleaning & Degreaser

- Circuit Board Protection

- Thermal Management Solutions

- EMI Shielding

- General Assembly Adhesives

- Elastomeric Materials

- Process Equipment: Potting & Coating Systems, UV/ Heat Curing, Plasma Treatment, Tape placement automation, and cleaning machines

Technical Added Value to customer

Prostech offers customized material and process equipment solutions with engineering support throughout R&D, production process optimization, and performance validation. Our in-house lab located in Alabang, Muntinlupa is equipped to conduct electronics material testing, application simulation, and adhesive validation, helping customers reduce the need for onsite trials and accelerate implementation.

International Supply Chain Advantage

Regional warehouse hubs across Vietnam, Singapore, Malaysia, and the Philippines ensure cross-border reliable supply. In Philippines PEZA-bonded warehouse located at Lima Industrial Park, Batangas enables Prostech to provide responsive, demand-based delivery and significantly shortens standard lead time for Philippines customers.

Need help selecting the right product or solution?

Typical Properties

| Properties | GSP-300 |

|---|---|

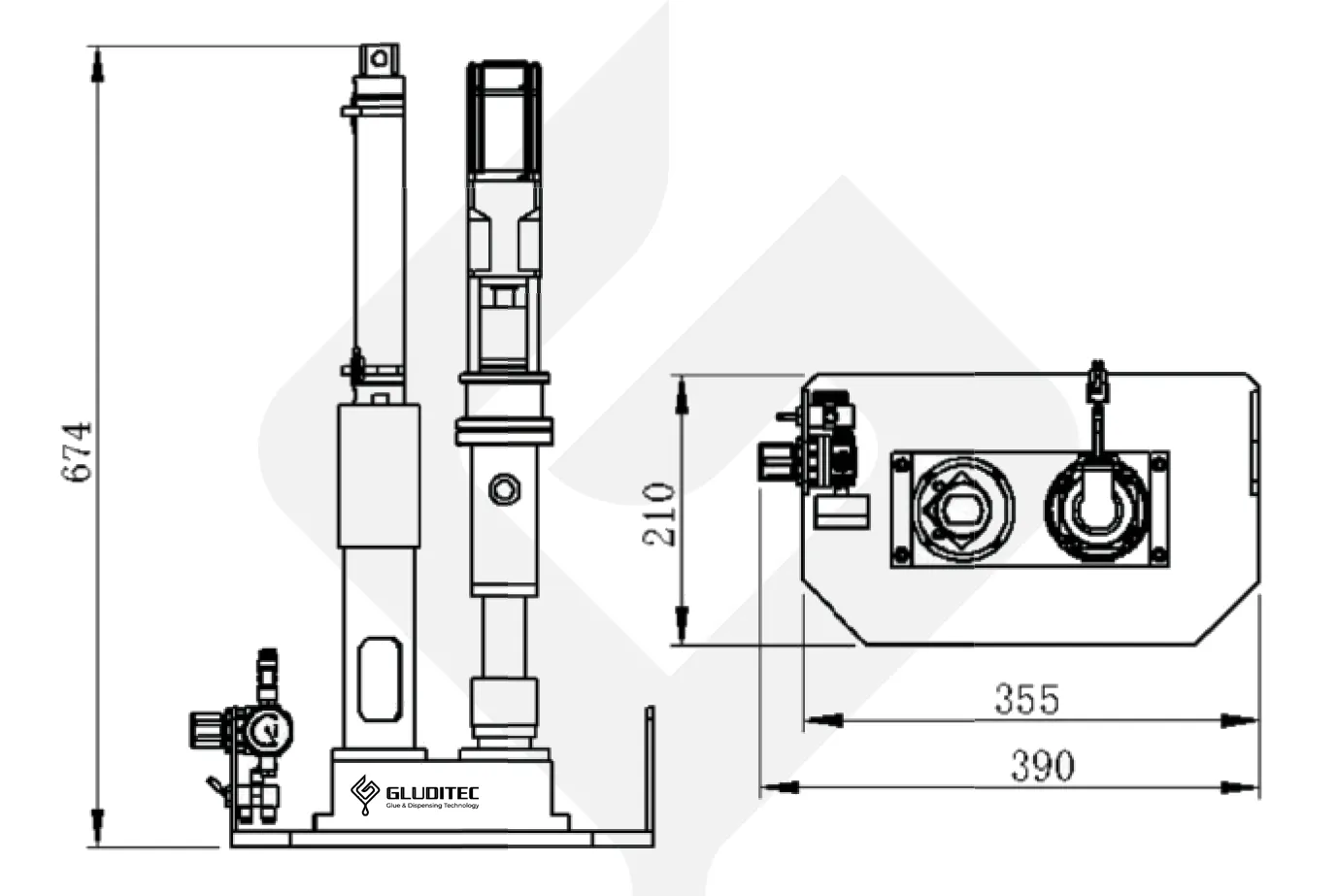

| External dimensions | L390 x W210 x H674 mm |

| Power | 400W |

| Air Input | 0.5 ~ 0.7 MPa |

| Cylinder thrust | 50kg (at air pressure 0.5MPa) |

| Track length | 1500mm, customizable |

| Pumping method | Cylinder push + progressive cavity pump self-priming |

| Glue packaging | 300cc/ 330cc packing |

| Output Volume Options | 1.5cc/ 6cc/ 9cc |

| Rotor material | Stainless steel |

| Stator material | Stainless steel + Extra wear-resistant rubber |

| Sealant material | PEEK/TEFLON/ Special rubber |

| Structural part material | Aluminum alloy anode/ stainless steel |

| Applicable material viscosity | <1,500,000 cps |

| Hardness of applicable material | <60HRC |

| Control mode | PLC control |

| Monitoring method | Closed-loop control of pressure sensors |

| Alarm alert | Lack of material alarm, abnormal pressure alarm |

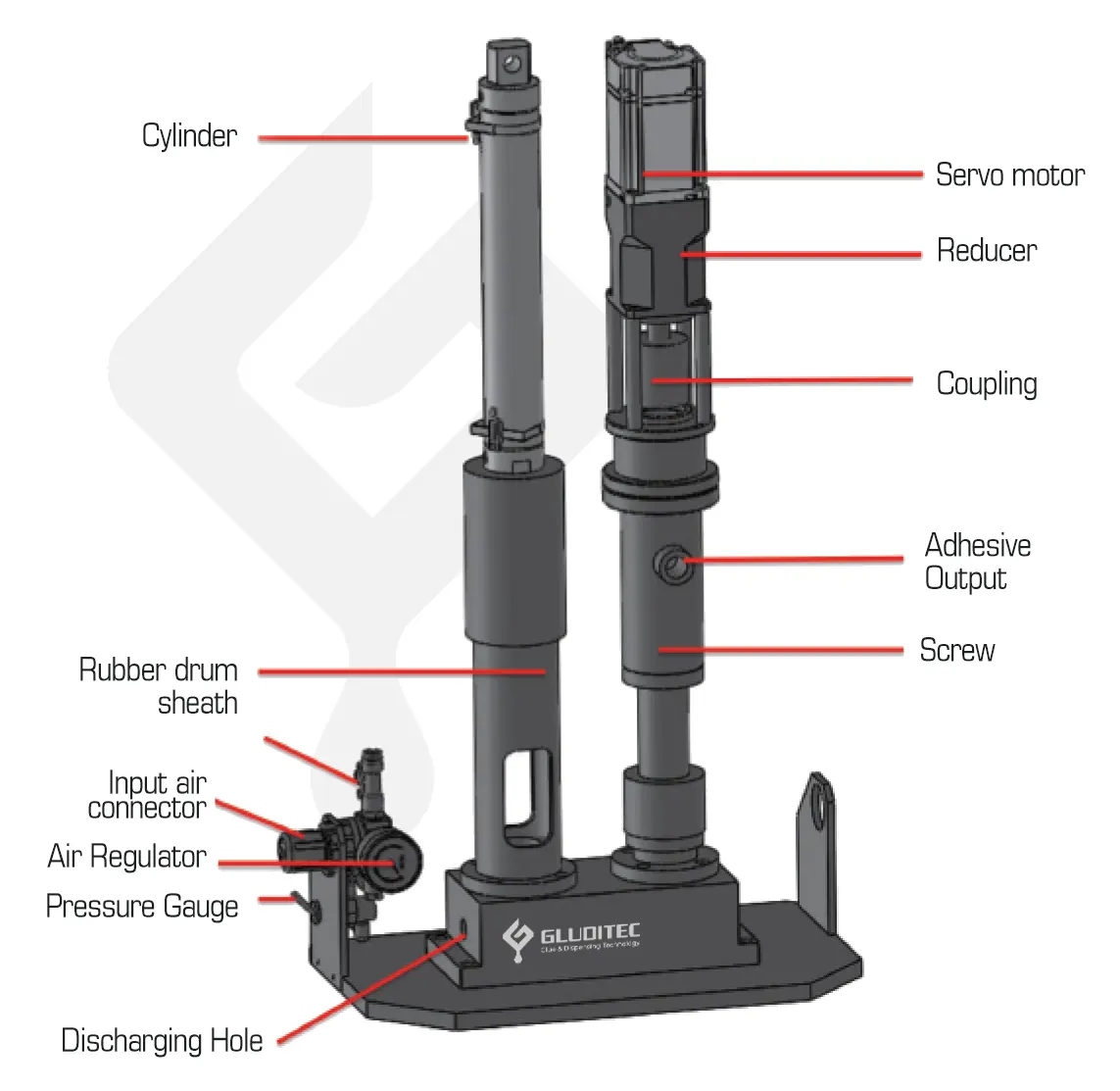

CONFIGURATION

DRAWING