The current industry has a strong need for weight savings in order to meet the regulations regarding the issue of the global environment. In response to the demand for lighter-weight material, as metal and glass are being replaced by lightweight plastics, the manufacturers toward the use of Polycarbonate (PC) – an engineering plastic with impact resistance, light transmission, and optical clarity. However, its surface can be prone to scratches, which can impair its visual appeal and functionality. This is where hard coating for polycarbonate comes into play.

1. What is hard coating?

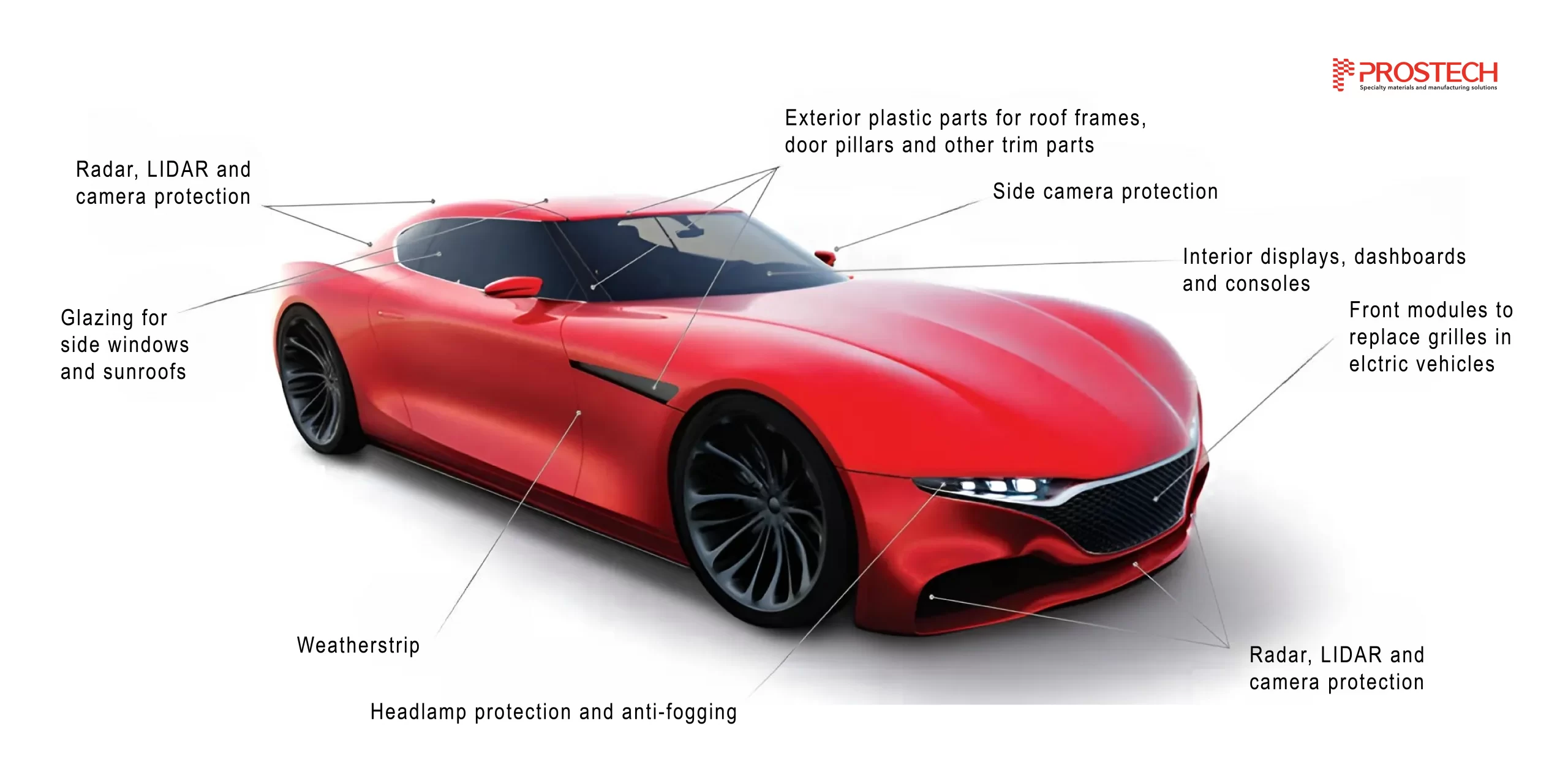

Hard coating for polycarbonate is a high-performance material that has undergone a special coating process to enhance its scratch resistance and abrasion resistance. This hard coating not only provides a protective layer that shields the scratch-resistant polycarbonate sheet from damage but also maintains the inherent benefits of polycarbonate, such as its excellent light transmission and impact resistance. Hard-coated polycarbonate offers manufacturers the ability to replace glass and metal with lightweight plastics in several demanding applications, including lighting, glazing, exterior trim, sensor covers, interior parts, and new front module applications.

2. Advantages of hard coating

The hard coating process involves applying a protective layer to the polycarbonate, enhancing its durability and resistance to various forms of damage. This process does not compromise the inherent properties of polycarbonate but rather enhances them, making hard-coated polycarbonate a superior material for many applications.

- Enhanced Scratch Resistance: One of the primary benefits of hard-coated polycarbonate is its enhanced scratch resistance. During the curing process, silicone molecules typically crosslink, forming a three-dimensional network throughout the layer. This network acts like a web, distributing the force of a scratch or impact more evenly across the coating. Compared to uncoated polycarbonate plastic, silicone hard coating significantly improves scratch resistance. This ensures that this abrasion-resistant polycarbonate maintains its optical clarity and aesthetic appeal over time, even in demanding environments.

- Abrasion Resistance: Silicone hard-coated polycarbonate exhibits abrasion resistance. This means it can withstand continuous contact with harsh substances or conditions that would typically wear down other materials.

- Preserved Light Transmission and Optical Clarity: The hard coating process does not affect the high light transmission and optical clarity inherent to polycarbonate. This means that hard coated polycarbonate can still provide clear visibility, making it ideal for applications such as windows, protective screens, and optical devices.

- Improved Durability: Hard coating can also improve the overall durability of polycarbonate components. It can provide some protection against minor impacts and vibrations commonly. This can help extend the lifespan of these components.

- Improved Heat Resistance: Hard-coated polycarbonate can withstand high temperatures, making it suitable for applications exposed to heat. This heat resistance, combined with its other enhanced properties, makes hard-coated polycarbonate a versatile material that can meet the demands of various high-performance applications.

3. Disadvantages of hard coating

Besides those excellent benefits of hard coating materials, there are also some minor drawbacks such as:

- Cost: Hard coating materials for polycarbonate can add to the overall cost of regular polycarbonate due to the additional coating process. However, the enhanced durability and longevity often justify the extra cost.

- Compatibility: Some hard coating may not be compatible with all types of PC. Using an incompatible coating can reduce the protection effect or even damage the product. You need to choose a hard coating material that is suitable for your application.

Each industrial manufacturer requires unique characteristics for the hard-coated polycarbonate, from material to equipment for the hard coating process. Contact us to receive consultation about choosing suitable types of materials or equipment for your manufacture from our qualified experts.

3. Conclusion

The enhanced properties of hard-coated polycarbonate make it a versatile material that can be used in a wide range of applications. This innovative material boasts unmatched clarity while fending off scratches, abrasions, and even chemicals with ease. This powerhouse combination makes it the perfect choice for a variety of applications, transforming industries and enhancing your everyday life.

All over the world, hard-coated technology is enabling the innovative use of plastic materials in a variety of industries. In the transportation sector, hard coat-protected plastics can be found in automotive lighting, glazing, exterior trim, interior parts, and displays, providing lightweight and design flexibility and paving the way for multiple applications in the fuel-efficient automobiles of the future. In architectural applications, hard-coated plastic materials are contributing to energy efficiency and safety. In hand-held mobile devices and display technologies, where both lightweight and durability are critical factors, plastics with hard-coated technology are finding their way into touchscreen applications.

—————————————–

For more information, contact us to talk with our glue experts: