The automotive industry has a strong need for weight savings to meet the regulations regarding the issue of the global environment. In response to the demand for lighter weight automotive bodies, as metal and glass are being replaced by lightweight plastics, the manufacturers toward the use of Polycarbonate (PC) an engineering plastic with superior transparency, impact resistance, and heat resistance, in automotive glazing is picking up steam. However, the relative cost allowance and long-term reliability of PC (durability, weather resistance, and abrasion resistance) compared to glass are bottlenecks to its market penetration.

You can find related information about Hard coating methods for Poly carbonate at the article: Hard coating for Polycarbonate – New Technology, New Breakthrough

The automotive encounters many hazards on the road, from flying gravel to car washes; exposure to sunlight, might encounter various chemicals on the road…so the automotive industry requires materials that can withstand harsh conditions while providing safety and performance, but PC is weak.

To solve that problem, silicone hard coat for automotive were born. Thermoset silicone hard coat with improved weather resistance and abrasion resistance, chemical resistance, which are weaknesses of PC.

1/ Application

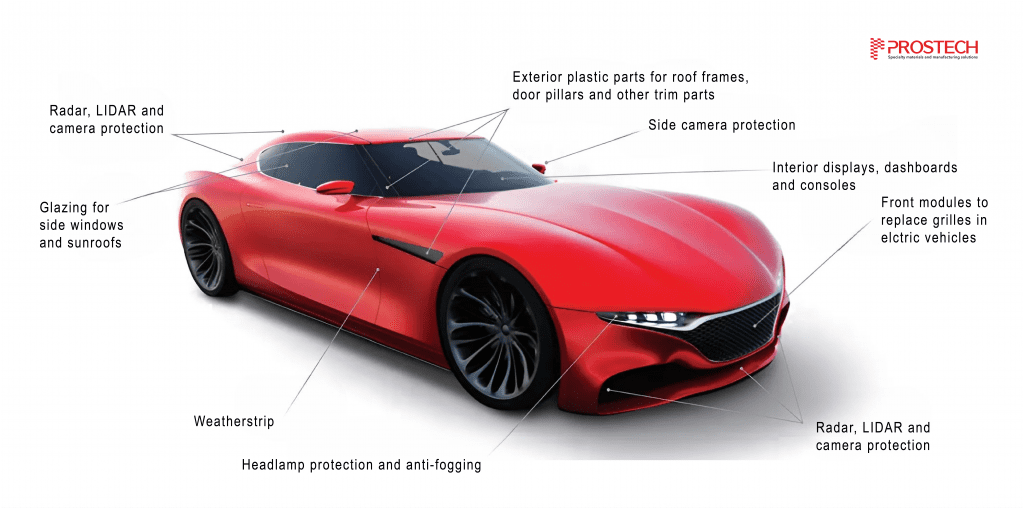

Silicone hardcoats offer automotive manufacturers the ability to replace glass and metal with lightweight plastics in a number of demanding applications.

For engineered plastics, such as polycarbonate (PC) or PMMA, Prostech’s solution improve the durability and performance of plastics by helping them maintain their color, gloss, light transmission and physical properties, while enhancing weatherability, cleanability and resistance to abrasion, chemicals and solvents.

Prostech’s solution enables the innovative use of plastics in a variety of automotive applications including:

- Lighting

- Glazing

- Interior parts

- Exterior parts

In addition, Prostech also provides hard coating solutions for automotive metallis part such as aluminum alloys or anodized aluminum. They provide excellent corrosion resistance, abrasion resistance and chemical resistance for aluminum exterior parts including:

- Door pillars

- Door sills

- Belt lines

- Roof rails

- Window trim

Each component in an automobile requires different types of materials, equipment, and hard coating processing techniques. Choosing the right materials and applying the appropriate techniques can help achieve optimal performance for the vehicle. Prostech is a trusted partner offering consultation on products and solutions for your manufacturing needs. Contact us to receive valuable information from our qualified experts.

2/ Conclusion

Hard coating solutions are becoming more and more popular for their ability to give a high abrasion resistance, protecting against UV damage, corrosion and give high visible automotive applications.

With a comprehensive range of chemistry platforms, Prostech offers the most application flexibility for hard coating solutions. Prostech ensures optimal performance and reliability in these critical materials solutions through advanced technology and meticulous attention to detail. With a focus on improving efficiency and improving the quality of life, Prostech’s hard coating solutions will bring you great experiences when using our products.

—————————————–

For more information, contact us to talk with our glue experts.