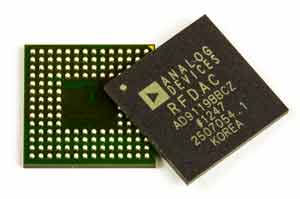

PCB assembly using ball grid arrays, BGAs requires a little more care as the contacts to be soldered are under the main chip and cannot be seen when in place.

At first sight soldering ball grid arrays, BGAs may seem to be difficult as the solder balls that solder onto the PCB are sandwiched between the BGA body itself and the circuit board.

However, PCB assembly using BGAs has been proved to work and work well. The soldering process and other areas of the PCB assembly may require to be slightly modified, but the benefits of using BGAs have been found to be quite significant, both in terms of reliability and performance.

The Ball Grid Array, BGA was introduced as a result of the pin count on many chips rising significantly. The pins on carriers like the Quad Flat Pack became very delicate and easy to damage. Also, PCB routing was difficult as a result of the close proximity of many leads. Using the whole of underside of the chip solved the issues of density on fragile chip leads in one go.

The BGA components provide a far better solution for many boards, but care is required in the PCB assembly process when soldering BGA components to ensure that the BGA is correctly soldered so that all the joints are correctly made.

What is a Ball Grid Array?

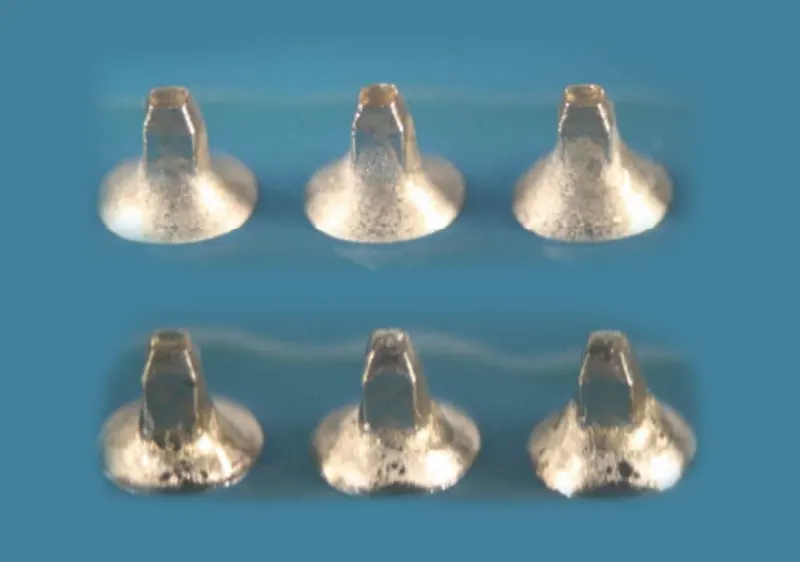

The Ball Grid Array or BGA, is a very different package to those using pins, such as the quad flat pack. The pins of the BGA package are arranged in a grid pattern and this gives rise to the name. In addition to this, rather than having the more traditional wire pins for the connections, pads with balls of solder are used instead. On the printed circuit board, PCB, onto which the BGA components are to be fitted there is a matching set of copper pads to provide the required connectivity.

BGA packages offer many advantages over their quad flat pack rivals and as a result, they are being used increasingly for the manufacture of electronics circuits:

- Improved PCB design as a result of lower track density

Track densities around many packages such as the quad flat pack become very high because of the very close proximity of the pins. A BGA spreads the contacts out over the full area of the package greatly reducing the problem.

- The BGA package is robust

Packages such as the quad flat pack have very fine pins, and these are easily damaged by even the most careful handling. It is almost impossible to repair them once the pins are bent owing to their very fine pitch. BGAs do not suffer from this as the connections are provided by pads with the BGA solder balls on them which are very difficult to damage.

- Lower thermal resistance

BGAs offer a lower thermal resistance between the silicon chip itself than quad flat pack devices. This allows heat generated by the integrated circuit inside the package to be conducted out of the device onto the PCB faster and more effectively.

- Improved high-speed performance

As the conductors are on the underside of the chip carrier. This means that the leads within the chip are shorter. Accordingly, unwanted lead inductance levels are lower, and in this way, Ball Grid Array devices are able to offer a higher level of performance than their QFP counterparts.

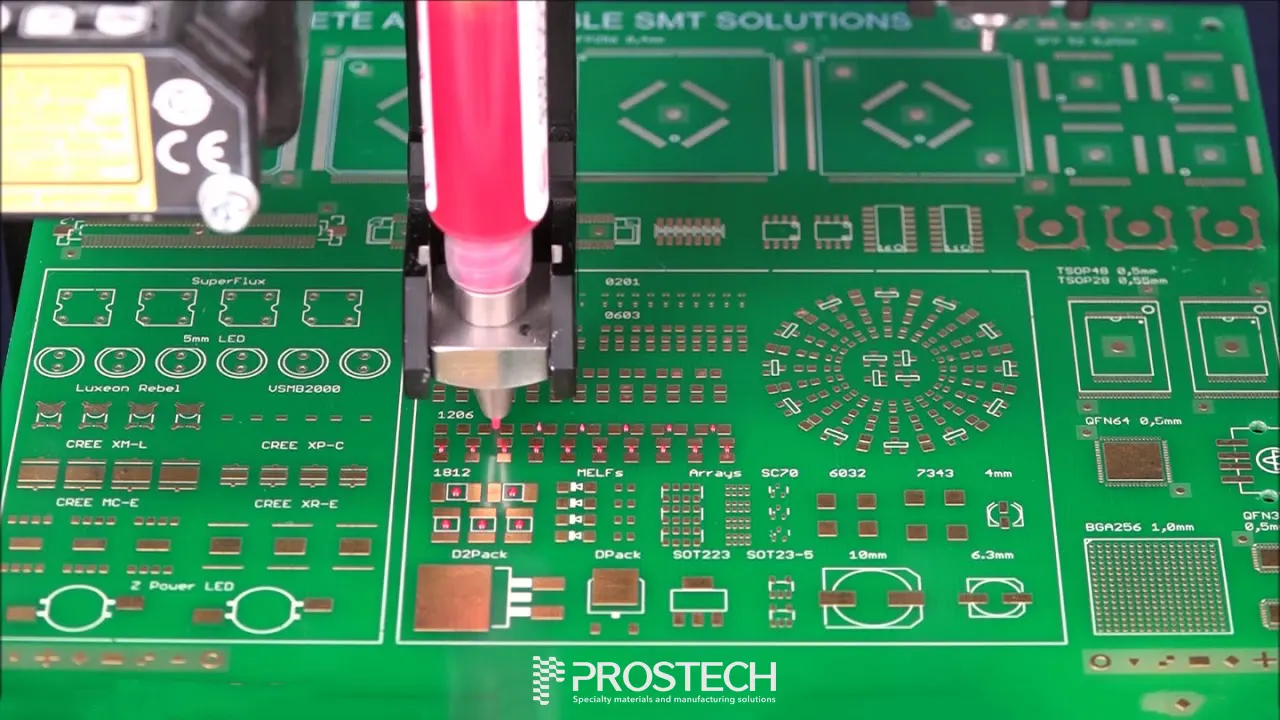

BGA solder process

One of the initial fears over the use of BGA components was their solderability and whether soldering BGA components could be made as reliable as soldering devices using more traditional forms of connection. As the pads are under the device and not visible it is necessary to ensure the correct process is used and it is fully optimized. Inspection and rework were also concerns.

Fortunately, BGA solder techniques have proved to be very reliable, and once the process is set up correctly BGA solder reliability is normally higher than that for quad flat packs. This means that any BGA assembly tends to be more reliable. Its use is therefore now widespread in both mass production PCB assembly and also prototype PCB assembly where circuits are being developed.

For the BGA solder process, reflow techniques are used. The reason for this is that the whole assembly needs to be brought up to a temperature whereby the solder will melt underneath the BGA components themselves. This can only be achieved using reflow techniques.

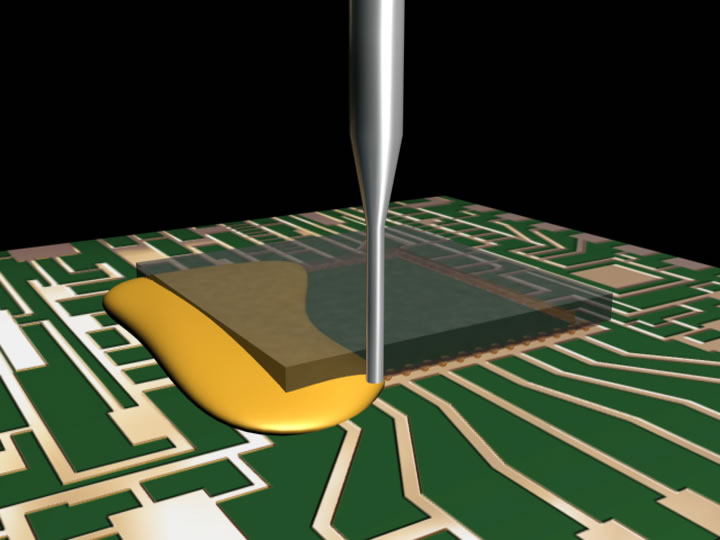

For BGA soldering, the solder balls on the package have a very carefully controlled amount of solder, and when heated in the soldering process, the solder melts. Surface tension causes the molten solder to hold the package in the correct alignment with the circuit board, while the solder cools and solidifies.

The composition of the solder alloy and the soldering temperature is carefully chosen so that the solder does not completely melt, but stays semi-liquid, allowing each ball to stay separate from its neighbors.

BGA solder joint inspection

BGA inspection is one area of the PCB assembly process that raised a considerable amount of interest when BGAs were first introduced.

BGA inspection cannot be achieved in the normal way using straightforward optical techniques because, quite obviously, the solder joints are underneath the BGA components and they are not visible.

It created a considerable degree of unease about the technology when it was first introduced and many manufacturers undertook tests to ensure that they were able to solder the BGA components satisfactorily. The main problem with soldering BGA components is that sufficient heat must be applied to ensure that all the balls in the grid melt sufficiently for every BGA solder joint to be satisfactorily made.

The solder joints cannot be fully tested by checking the electrical performance. While this form of test of the BGA solder process will reveal conductivity at that time, it does not give a full picture of how the BGA solder process has succeeded. It is possible that the joint may not be adequately made and that over time it will fail. For this, the only satisfactory means of the test is a form of BGA inspection using X-rays This form of BGA inspection is able to look through the device at the soldered joint beneath. As a result, Automated X-ray Inspection – AXI became a mainstream technology for checking PCB assemblies that included BGAs.Fortunately, it is found that once the heat profile for the solder machine is set up correctly, the BGA components solder very well and few problems are encountered with the BGA solder process.

BGA rework

As might be anticipated, it is not easy to rework BGA assemblies unless the correct equipment is available. If a BGA component is suspected as being faulty, then it is possible to remove the device. This is achieved by locally heating the BGA component to melt the solder underneath it.

In the BGA rework process, the heating is often achieved in a specialized rework station. This comprises a jig fitted with an infrared heater, a thermocouple to monitor the temperature, and a vacuum device for lifting the package. Great care is needed to ensure that only the BGA is heated and removed. Other devices nearby need to be affected as little as possible otherwise they may be damaged.

BGA technology in general and in particular the BGA soldering process have proved themselves to be very successful since they were first introduced. They are now an integral part of the PCB assembly process used in most companies for mass production and for prototype PCB assembly.

Contact us for more information about BGA’s updated technology

Hotline: (+84) 984 695 398

Email: gluexpert@prostech.ph