Custom Solutions to help you envision and build the most advanced and capable electric mobiles.

Today there is an ever-increasing trend toward the electrification of vehicles in the transportation industry. For electric vehicles (EVs) to gain more acceptance in the market, there have been ongoing efforts to increase the range and performance of EV’s to be similar to current internal combustion engine vehicles. Our range of solutions and services help EV engineers do just that.

The heart of any vehicle is the powertrain, and internal combustion engines (ICEs) have years of research and development behind them. For hybrid and electric powertrains, the journey has only just begun.

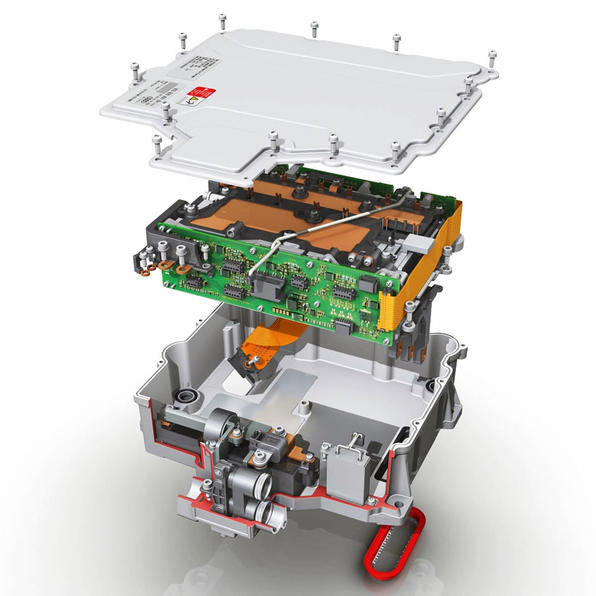

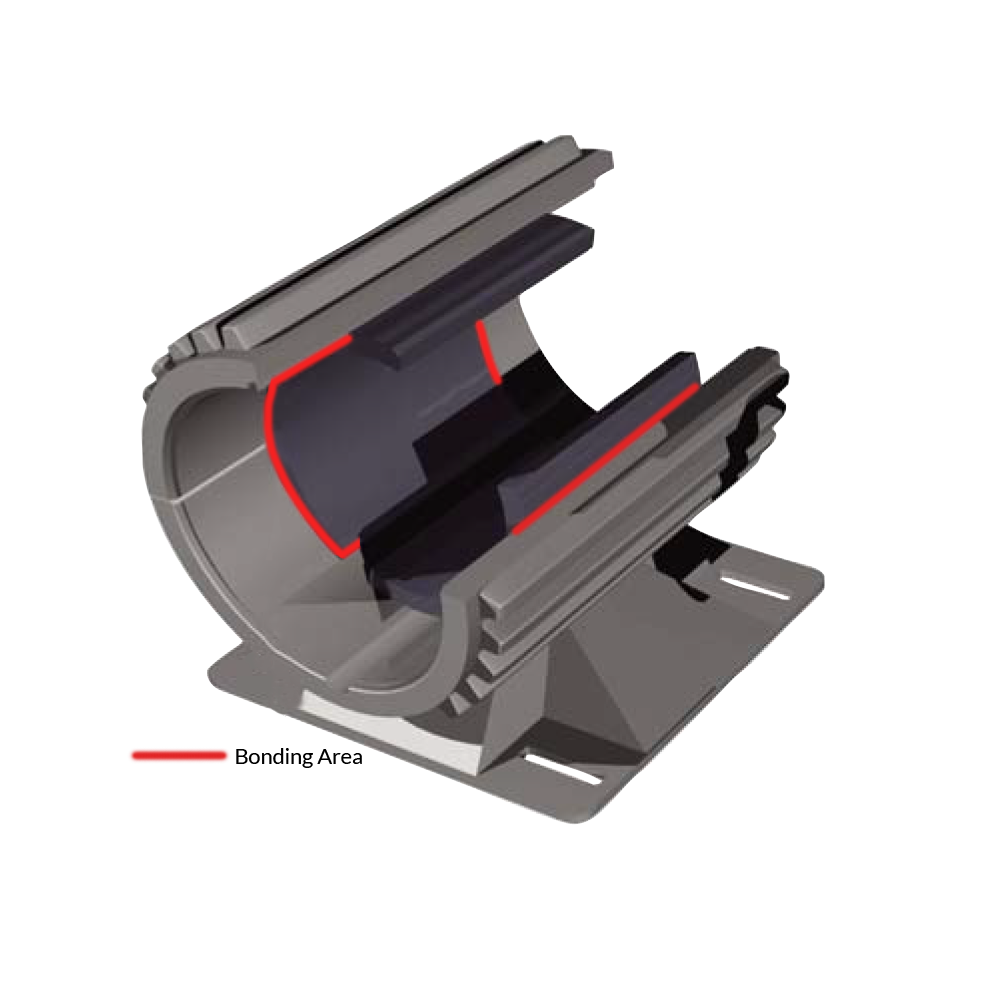

The structure of an EV powertrain can be understood by distinguishing between three major systems: the battery system, the electric motor (or electric drive system), as well as various power conversion electronic components (inverter, converter, on-board charger, battery management system).

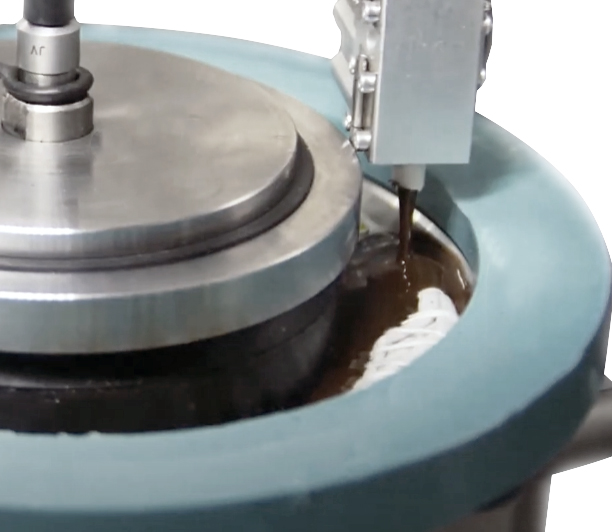

Key engineering challenges across EV powertrain components include efficient thermal management, integrating electric systems, miniaturization, total vehicle weight reduction, and ensuring safe and reliable vehicle performance. At the same time from a commercial perspective, electric vehicle prices need to be brought down by reducing overall system costs.

Hover over the spots to see more information