From Battery Cell to Battery Module, we solve every challenge of Cylindrical, Prismatic, Pouch Cell.

Thermal management and assembly process are two keywords appearing in almost discussion regarding battery systems. If these challenges are solved, critical end-consumer perceptions of range anxiety, as well as price and safety concerns, will be addressed through batteries that offer reliable and safe operation of the car in tandem with fast charging.

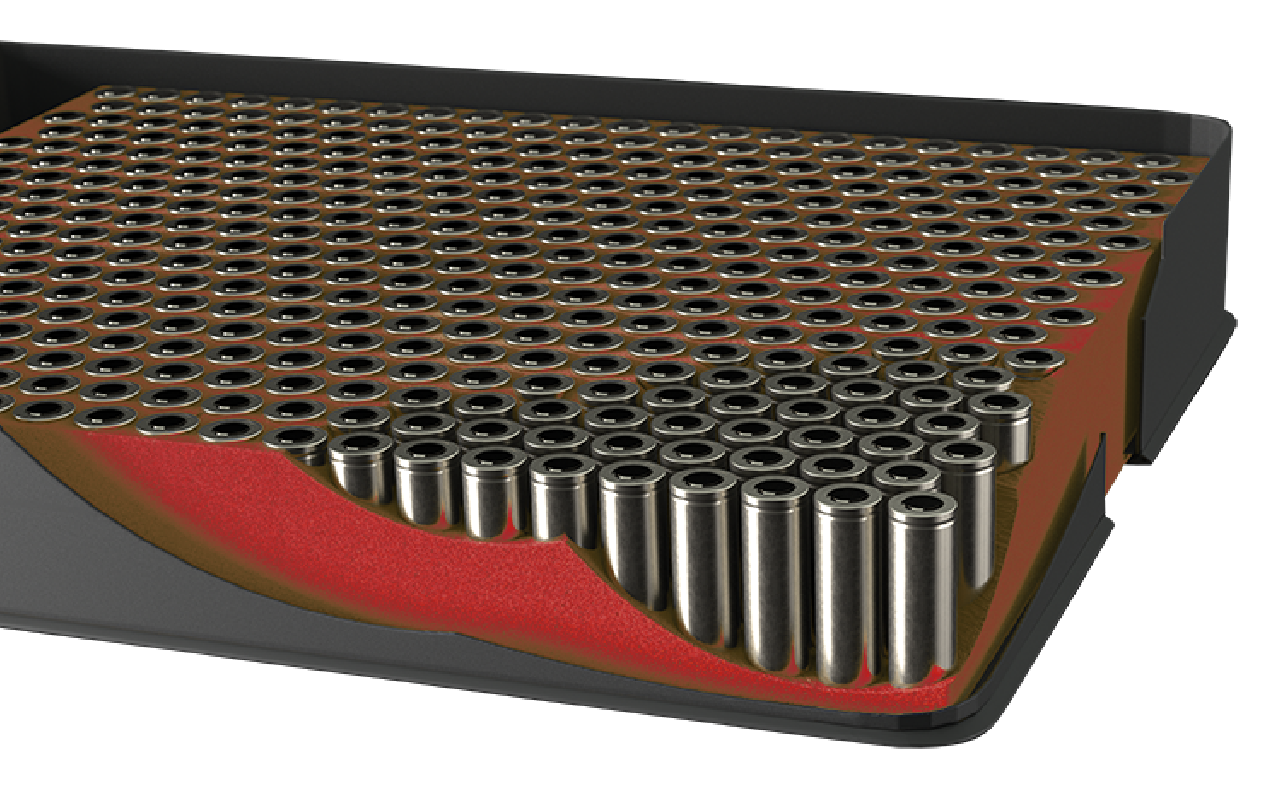

Battery designs vary, most notably in terms of the type of battery cells used – manufacturers typically use either cylindrical, prismatic, or pouch cells. Given the variety of designs, OEMs and Tier 1 suppliers face a common set of engineering and commercial challenges: cost reduction, lifetime performance optimization, safety and reliability, and seamless integration into the car body.

PROSTECH is confident to provide total solutions including thermal management materials, adhesives, sealants to support vehicle manufacturers and suppliers in addressing these challenges.

Hover over the spots to see more information