Electrical Disturbances are known as the most popular reason caused for the failure of a transformer. However, it is not known widely that heating generated by the loading of a transformer is the direct cause of the insulating degradation.

Thermal degradation results in the loss of physical strength of the insulation that, over time, will weaken the paper to the point where it can no longer withstand the mechanical duty imposed on it by the vibration and mechanical movement inside of a transformer.

As a result, it is essential to design an appropriate “cooling system” for the transformer at the very first step. Besides the most significant advantages of reduction in insulating degradation, good thermal management will help to:

- Increase dielectric strength

- Improve the structural integrity of the coils

- Reduce or eliminate winding noise

- Improve heat transfer

- Reduce partial discharge

- Provide increased environmental protection

Depending on the size and industry of the transformer, the thermally conductive method will be one of the two following methods.

Impregnation is the complete penetration of the process materials (generically called varnish or epoxy) into the windings of the transformer’s coils. This is often accomplished by using a Vacuum Pressure Impregnation (VPI) cycle.

Impregnated – Unpotted transformer

- Power transformer

- Distribution transformers

- Railway transformer

- Oil transformer

- Gas-insulated transformers

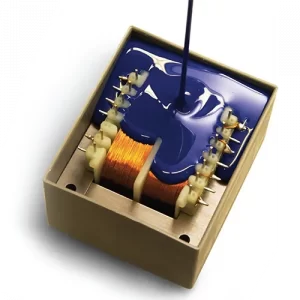

Potting & Encapsulation are the complete encasement by the process materials (generically called varnish or epoxy) onto the windings of the transformer’s coils. In simple terms, the process materials have a thicker, more complete coating than an impregnated transformer. Encapsulation can be done by performing two or more VPI cycles or using a higher viscosity process material. Sometimes “potted” will be used for “encapsulated”. A Cast Coil transformer would be both impregnated and encapsulated.

Potting Transformer – Small type

- Print transformers

- Toroidal transformers

- Lighting transformer

- Welding transformer

- Instrument transformers (LV & MV)

However, it is essential to note that there is not an industry standard for encapsulation. A winding can be encapsulated, it can be impregnated, or it can be encapsulated and impregnated. Choosing between impregnating and encapsulating will depend on the practical situation and experience of your partner.