Liquid Crystal Displays (LCDs) are crucial components in a variety of devices, including large-screen televisions, computer monitors, laptops, mobile phones, and other portable gadgets. Despite appearing to be a minor component, the LCD gasket plays a vital role in maintaining the performance and longevity of these displays. It protects the sensitive electronics by sealing out air, water, dust, light, and electromagnetic interference (EMI), ensuring the device functions optimally and remains durable over time.

Prostech offers a range of gasket solutions designed to seal and protect touchscreens and displays in TVs, monitors, tablets, and laptops. These gaskets serve multiple functions, including sea, load distribution, gap filling, mechanical shock protection, and cushioning against over-pressures.

Sealing Functions of Gaskets for Touchscreens and Electronic Displays

Gaskets for touchscreens and electronic displays perform the following sealing functions:

LCD Gasket for Sealing against dust and moisture

Sealing against dust and moisture is crucial for display gaskets because displays operate in diverse environments, from indoors to outdoors. The sealing requirements vary by application: for instance, a computer screen gasket needs to block light and resist water to protect against spills from cleaning fluids and drinks. In contrast, a handheld device gasket must be highly waterproof to function effectively win the rain.

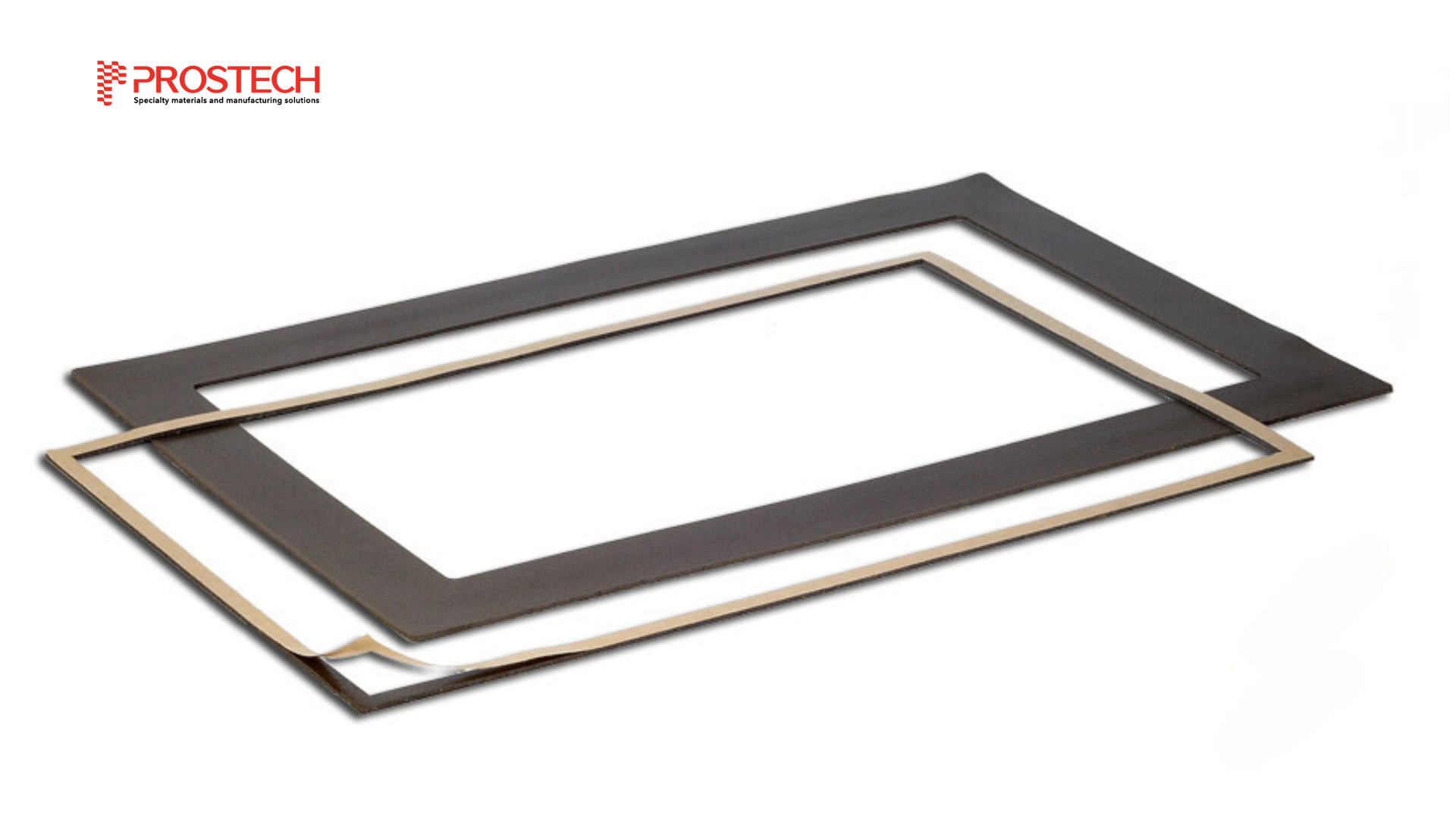

LCD Gasket for Gap filling

Gap filling between the screen, display, and bezel compensates for any device inconsistencies. These gaskets also act as flexible spacers, preventing the multi-layered LCD glass from contacting the frame. This ensures image quality, stability, and shock absorption.

LCD Gasket for Load distribution and over-press protection

The gasket evenly distributes pressure from the housing or bezel across the display, preventing pressure points that could cause image distortion or electrical faults. It also cushions the display when pressed forcefully, dispersing the pressure to protect against concentrated stress or localized damage.

Sealing and Gasketing Products

Common Gaskets Materials for Touchscreens and Electronic Displays

To ensure optimal performance and protection, it’s essential to choose the right gasket material for touchscreens and electronic displays. Here are some of the most common materials used:

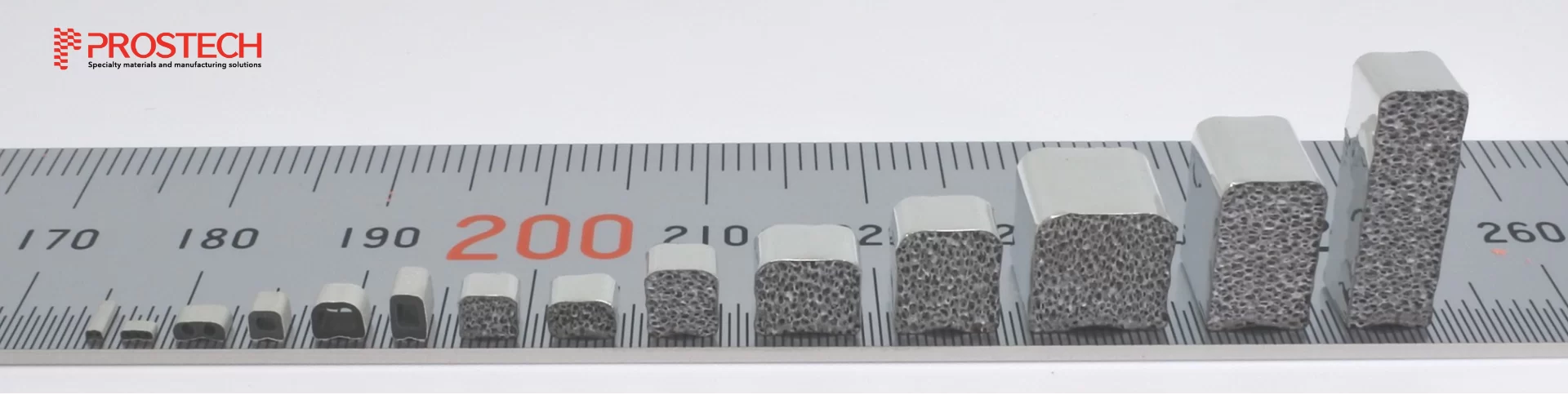

Foam for LCD gasketing

Foam is effective for gap filling and cushioning, as well as being lightweight and cost-effective. It is commonly used in laptops, monitors, and other consumer electronics where cost efficiency and adequate protection are priorities. As consumer electronics become sleeker and more intricate, engineers are seeking foam materials that are not only slimmer and lighter but also softer and more capable of compression.

VHB Tape for LCD Gasketing

VHB tape stands out as an exemplary adhesive solution, available in a range of thicknesses and featuring a feather-light construction. It is resilient to water, UV light, and extreme temperatures. Commonly used in smartphones, tablets, and other portable devices where a strong, lightweight bond is required, VHB tape is also utilized in automotive displays, building facades, and other applications where durability and strength are crucial.

Silicone Adhesive for LCD Gasketing

When solid gaskets aren’t suitable for intricate designs, a modified silicone adhesive emerges as a practical alternative. It offers strong adhesion to various surfaces like metals and plastics, including PC, PMMA, ABS, and more. Its high flexibility helps absorb vibrations effectively. With minimal water permeability, UV resistance, and a wide temperature tolerance range, modified silicone serves as a durable touchscreen gasket, perfect for outdoor applications.

Touchscreen applications, though functionally similar, demand distinct gasket protections tailored to their specific usage environments. For instance, indoor consumer touchscreens typically need dust gaskets that offer some degree of shock protection. However, outdoor touch screens and industrial control displays require more robust gasket solutions. Outdoor devices must withstand heavy rain, UV radiation, ozone exposure, and maintain flexibility across diverse temperatures.

Searching for the ideal material for your project? With access to a wide range of gasket materials for touchscreens, Prostech can fulfill the functional needs of diverse industries and demanding applications.

Factors Influencing LCD Gasket Material Selection

When selecting gasket materials, several key factors must be considered to ensure optimal performance and compatibility with specific applications:

- Adhesion Properties: Ensures the gasket bonds effectively to the surfaces, providing a secure seal.

- Thickness: Critical for proper fit and function within the assembly.

- Thermal Properties: Determines gasket material stability and performance at varying temperatures.

- Weather Resistance: Materials must be chosen based on their ability to withstand environmental conditions such as UV light, moisture, and extreme temperatures.

- Special Properties: Some applications may need gaskets with specific functionalities beyond sealing, such as electrical conductivity or fire resistance.

- Assembly: Ensures that the gasket maintains its shape and effectiveness throughout its lifespan.

- Cost and Availability: Budget constraints and gasket material availability can also impact the selection process.

Prostech offers comprehensive services to fulfill your touchscreen or electronic gasketing requirements. Contact us to discuss your specific needs and let us assist you in selecting the optimal combination of materials, thickness, and gasket shapes for your application.

[contact-form-7 404 "Not Found"]