Polyolefin and Teflon are two distinct types of polymer materials with unique properties and applications in industrial manufactures. One common challenge users often encounter is the difficulty of adhesion exhibited by these materials, posing significant obstacles in the manufacturing process. This article will analyze the compositions to explain the reasons behind their adhesion challenges and propose specific and practical solutions within the production process.

A. Why are Polyolefin and Teflon difficult to adhere?

1. Polyolefin

- Polyethylene – PE: Surface energy: 31mJ/m2

- Polypropylene – PP: Surface energy: 29 mJ/m2

To date, polyolefin remains the most common plastic material with superior properties and wide-ranging applications. However, the non-polar nature of polyolefin is one of its major limitations.

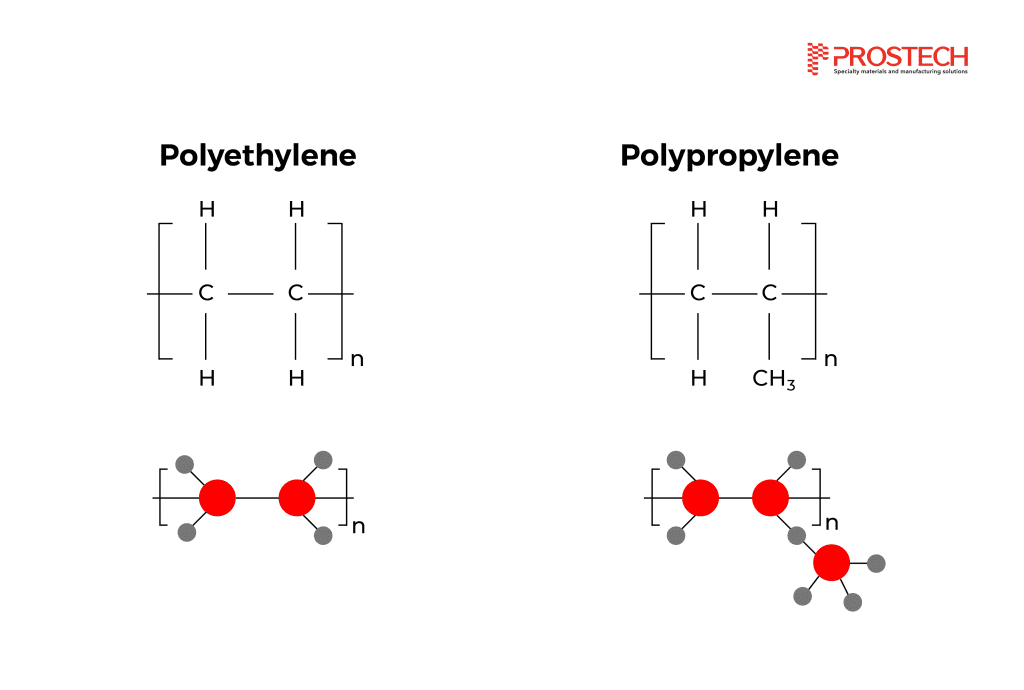

Polyolefin is a type of polymer originating from olefin, a type of non-saturated hydrocarbon, consisting of ethylene and propylene. Polymers within the polyolefin group typically have straight or nearly straight chain structures, and they are often non-polar or weakly polar. This makes them suitable for various applications in industries. PP (polypropylene), PE (polyethylene), HDPE (high-density polyethylene), LDPE (low-density polyethylene), BOPP (biaxially oriented polypropylene), OPP (oriented polypropylene), XLDPE (extra-low-density polyethylene) … all belong to the group of polymers commonly referred to as polyolefin.

Straight-chain polymers typically have long and uniform molecular structures, without any “knots” within the molecular structure to make them easily bend or deform. This gives them greater chemical resistance compared to polymers with more polar or branched molecular structures. This is also why PE and PP are often used for food packaging such as films and containers. Straight-chain polymers usually have less mobility compared to polymers with polar or branched structures. This reduced mobility makes them less likely to adhere to other surfaces and difficult to bond. The flat surfaces of straight-chain polymers typically lack polar groups such as hydroxyl (-OH) or amine (-NH2) groups positioned for easy contact with other surfaces. This reduces the interaction between polymer molecules and other materials, causing difficulties in the bonding process.

2. PTFE- polytetrafluoroethylene (Teflon)

- Surface energy: 19mJ/m2

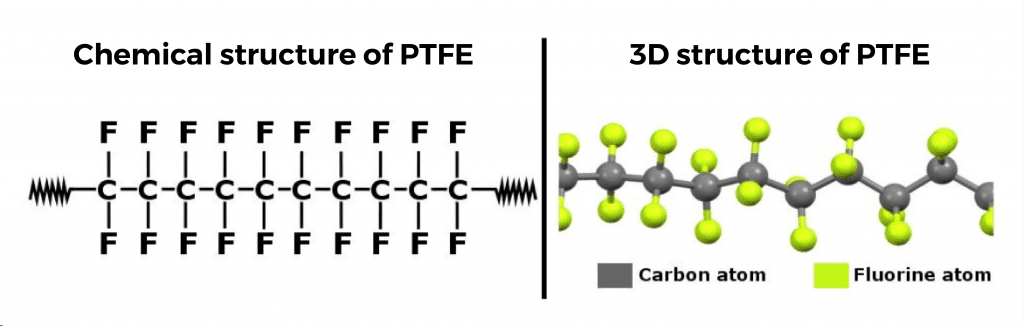

PTFE, or polytetrafluoroethylene, is a type of polymer known as a perfluorocarbon plastic. In perfluorocarbon plastics, all carbon atoms in the main chain of the polymer are completely bonded to fluorine atoms. The carbon-fluorine bond (C-F bond) is so strong that neither oxygen nor ultraviolet radiation has enough energy to break it. The strength of this bond is the source of its chemical inertness and good aging properties. The distribution of fluorine atoms around the carbon polymer framework helps balance negative and positive charges, making PTFE non-polar. Non-polar materials do not attract polar substances, such as water. This fully fluorinated polymer has a low surface energy, making it unwettable by water. PTFE is not known to have any soluble substances.

PTFE is chemically inert. It has low friction coefficient, meaning it is very smooth to touch. It operates within a wide temperature range and has good aging properties. It is porous, gas-permeable, durable, hydrophobic, biocompatible, and weather-resistant.

Fluorine atoms are large and bond very strongly with carbon, creating a highly stable molecular structure with natural non-stick properties. This makes the surface of Teflon quite resistant to adhesion and difficult to bond with other materials.

Additionally, Teflon also exhibits good chemical resistance and high heat resistance, making it an ideal material in many applications such as fluid conduits, non-stick cookware, and medical applications. However, the non-stick properties of Teflon also pose challenges in adhering it to other materials, requiring special surface preparation and adhesives to ensure good adhesion.

Selecting the appropriate adhesive type and application technique for Polyolefin and Teflon materials is equally vital to ensure robust bonding. Prostech, with experienced adhesive experts, stands to provide solutions regarding suitable adhesive types and appropriate application methods tailored to your manufacturing processes.

B. How to bond these materials?

1. Polyolefin

- Use acrylic structural adhesive

-

- Low surface energy plastic bonding

- No need for surface treatment by flame, corona, or plasma

- 1:1 mixing ratio is easy

- Non-hazardous during transportation

- Ideal for bonding various surface types

- Easy to use

- Fully cures at room temperature

- Good chemical resistance

- Good impact strength

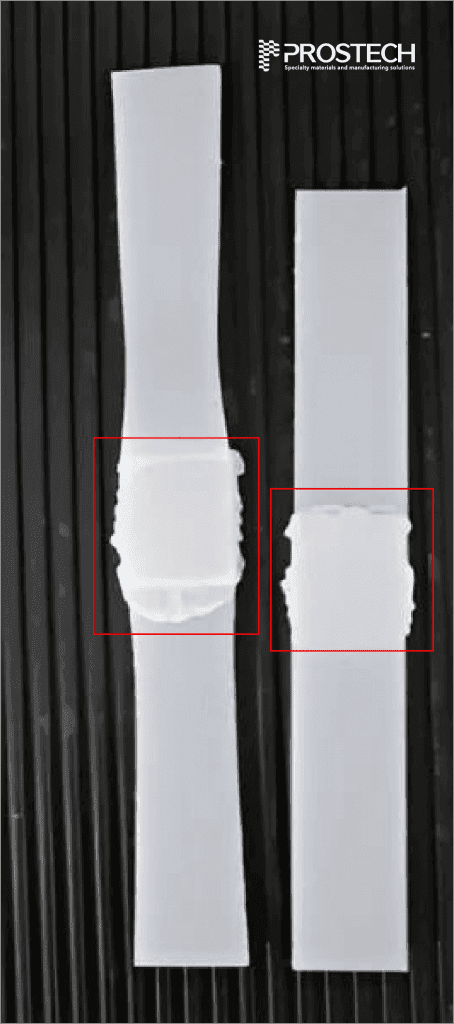

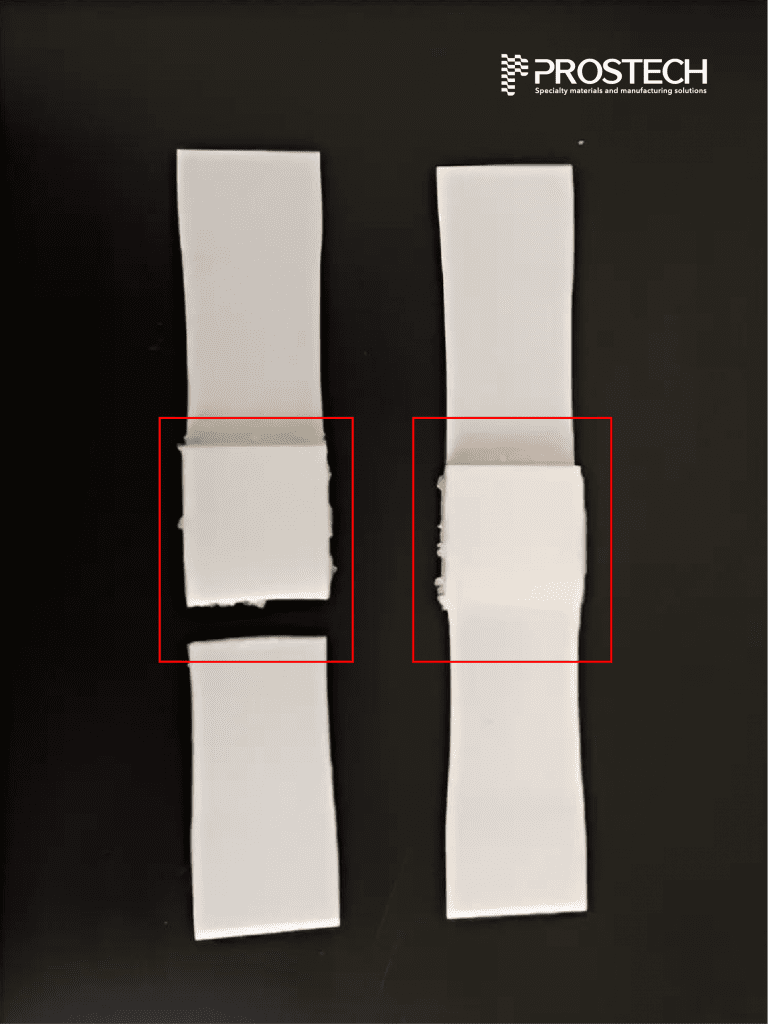

The adhesive can bond two surfaces in less than 10 minutes. Some products have longer open times for bonding larger surfaces. Some products are suitable for small gaps or have minimal odor to minimize user discomfort. Acrylic structural adhesives offer good impact resistance and environmental durability. They can also be used to bond polyolefin to various other substrates.

- Other adhesives for polyolefin include cyanoacrylate, epoxy, and UV adhesives.

-

- Use a primer with cyanoacrylate adhesive for bonding. Cyanoacrylate nearly instantaneously bonds and provides good adhesion with surfaces pre-treated with primer. The bonds resist non-polar solvents but are not as resistant to polar solvents.

- Experiment with surface treatments like flame, corona, or plasma to use epoxy and UV adhesives. Prefer epoxy with flexible properties.

2. PTFE- polytetrafluoroethylene (Teflon)

- Acrylic structural adhesive products are specifically developed for low surface energy polyolefins and PTFE.

- Bonding PTFE – Recommendations for surface preparation and bonding:

- If acrylic is unsuitable for your application, use primer and only use with cyanoacrylate adhesive. Or use fluorocarbon etching agents like “Tetra-Etch” to expand bonding options to other adhesive technologies. Surface treatments such as Corona, flame, plasma, and abrasion hardly improve adhesion with PTFE.

- Note: Besides surface preparation requirements, bonding materials like PP, PE, and Teflon with acrylic can be enhanced by new adhesive technologies from us. Prostech offers a wide range of acrylic products which are suitable for each industrial application. Contact us to receive valuable information and consultation from our experts.

—————————————–

For more information, contact us to talk with our glue experts.