Kunshan Hexin HX-700FQ

HX-700FQ is a high-speed thermal paper slitting and laminating machine featuring photoelectric tracking, EPC control, and magnetic tension management. It offers multifunctional slitting, accurate lamination, and automated monitoring for continuous operation.

HX-700FQ Features:

- Slitting and laminating with separate or simultaneous function

- EPC ultrasonic sensor and magnetic tension control

- Auto stop with length counter

- Advanced control with Siemens PLC and Schneider electronics

- Optional friction shaft and safety guards

HX-700FQ Applications:

- Thermal paper rolls, PE films, and adhesive tape slitting

- Label, packaging, and converting applications

About Prostech

Prostech Philippines is a one-stop solution provider for specialty materials and equipment across electronics manufacturing, from PCBA to final assembly. Our core material and equipment solutions include:

- PCB Assembly Materials

- Cleaning & Degreaser

- Circuit Board Protection

- Thermal Management Solutions

- EMI Shielding

- General Assembly Adhesives

- Elastomeric Materials

- Process Equipment: Potting & Coating Systems, UV/ Heat Curing, Plasma Treatment, Tape placement automation, and cleaning machines

Technical Added Value to customer

Prostech offers customized material and process equipment solutions with engineering support throughout R&D, production process optimization, and performance validation. Our in-house lab located in Alabang, Muntinlupa is equipped to conduct electronics material testing, application simulation, and adhesive validation, helping customers reduce the need for onsite trials and accelerate implementation.

International Supply Chain Advantage

Regional warehouse hubs across Vietnam, Singapore, Malaysia, and the Philippines ensure cross-border reliable supply. In Philippines PEZA-bonded warehouse located at Lima Industrial Park, Batangas enables Prostech to provide responsive, demand-based delivery and significantly shortens standard lead time for Philippines customers.

Need help selecting the right product or solution?

Typical Properties

|

Max. Unwinding Width |

700mm |

|

Max. Unwinding Dia |

1000mm |

|

Max. Rewinding Dia |

160mm |

|

Min Slitting Width |

25mm |

|

Machine Max. Speed |

110m/min |

|

Main Power |

2.95kw |

|

Unwinding Shaft |

3’’ (76mm) air-expanding shaft |

|

Rewinding Shaft |

0.5’’, 1’’ or as your request |

|

Weight |

1500kg |

|

Dimension |

2000*1700*1500mm |

CONFIGURATION

|

Name |

Model |

Pieces |

Remark |

|

Computer System |

PLC(Siemens)+4DA+7”Touch Screen(Taiwan)+ Synchronic(Korea) |

1Set |

Siemens+ Weinview |

|

Motor |

2 Sets |

Siemens from Germany |

|

|

Frequency Inverter |

2 Sets |

YASKAWA From Japan |

|

|

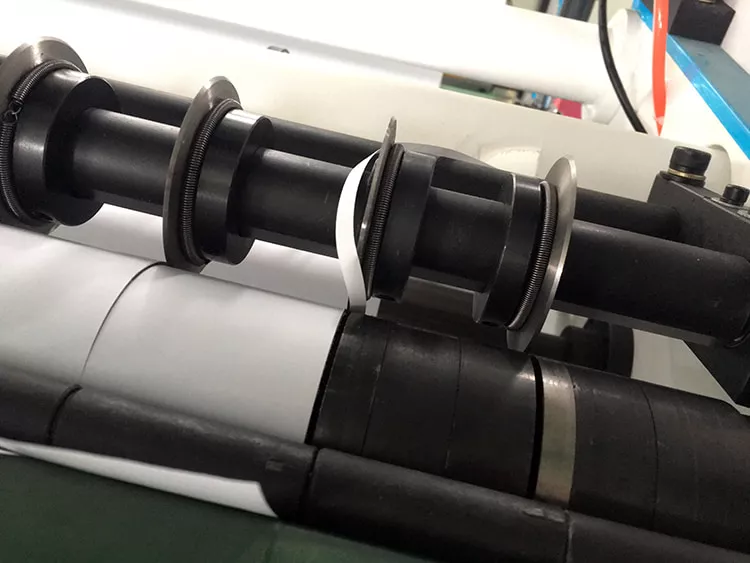

Upper/Lower Round Knife |

15 Sets |

||

|

Brake |

From Taiwan |

||

|

Sensor |

2 Sets |

||

|

Tension control |

3 Sets |

||

|

Chuck |

Self expandable chuck |

1 Set |

From Taiwan |

|

Magnetic Clutch |

2 Sets |

From Taiwan |

|

|

Low Voltage Electrical Switch |

SCHNEIDER |

||

|

Blower |

1 Set |

China |

|

|

Cylinder |

Airtac from Taiwan |

||

|

Air Pressure Valve |

SMC from Japan |

||

|

Relay |

CHNT |

Slitting knife