Challenge

The risks to chip integrity during transportation are significant due to the complex architecture. During the pick-up process, many failures happen such as die migration, cracking, and oxidation.

The electronics industry is making a tremendous investment in surface mount technology. The reasons for this investment include cost savings resulting from the automated component placement and increased density of PCB layout due to smaller package sizes. Today’s placement machines can pick and place thousands of components per hour with a very high degree of accuracy. To achieve this performance, the component delivery system must be capable of feeding parts at high speeds in a consistent orientation, positively indexed to the demands of the machine. The leads of the components must be protected from damage during shipment, handling, and placement.

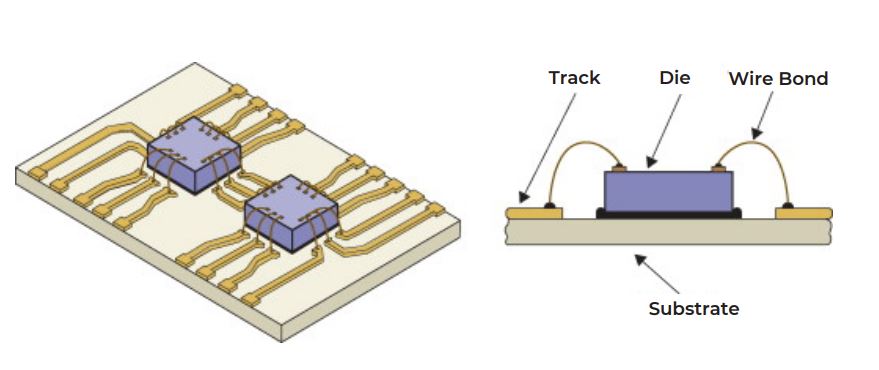

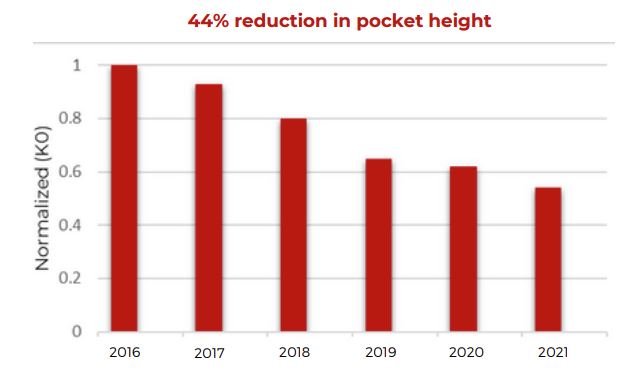

Chiplet design – a response and a driver for smaller, thinner chips

Pocket sizes have decreased dramatically in less than a decade. Chiplet integration allows for novel constructions using re-distribution layer (RDL), Si interposers and substrates associated with advanced packages, as well as integration platforms such as 2.5D/3D, fan-out and high-density flip-chip designs Safe and secure transport between the stages of the semiconductor fabrication process is critical for maximizing chip and chipset yield. As chip architecture evolves to 2D, 2.5D, and 3D in pursuit of a smaller footprint, better power management, and overall performance, the risks to chip integrity during transportation are significant due to the complex architecture.

Solution

Our latest semiconductor chip transport solutions start with carrier tapes to help prevent chip migration in thin package applications. They also include exciting capabilities for pre-barcoding that can help customers save time and improve crucial data analysis. Plus, we provide a comprehensive range of standard and custom cover tapes and precision carrier tapes to maximize yield even for irregular die sizes and pocket shapes.

Carrier tape

Polycarbonate Carrier tapes are available in a range of precision-manufactured designs and solutions to help minimize die migration and cracking and to help reduce pick-up failure. Plus, these tapes are available in transparent form, are compatible with clean room use, and can offer additional features such as traceability that meet the needs of your manufacturing processes.

Prostech offers a full array of non-conductive and static dissipative products with precision pocket designs for various components. We can also custom design a carrier tape to accommodate your specific needs and help ensure a smooth taping and pick and place process.

Versatile carrier tapes and cover tapes for semiconductor transport

![]()

Cover tape to help protect electrical and electronic components during transport and storage. Our cover tapes offer excellent sealing properties and smooth peel force to help ensure efficient pick and place operations.

The cover tapes include non-conductive and static dissipative products with heat-activated (HAA) or pressure-sensitive adhesives (PSAs).

Tape & Reel Product Information