Conformal coating – Why it matters

Over other popular electronic and electrical protection methods

Mabuhay Filipino friends!

Contact our Philippines team today

Over other popular electronic and electrical protection methods

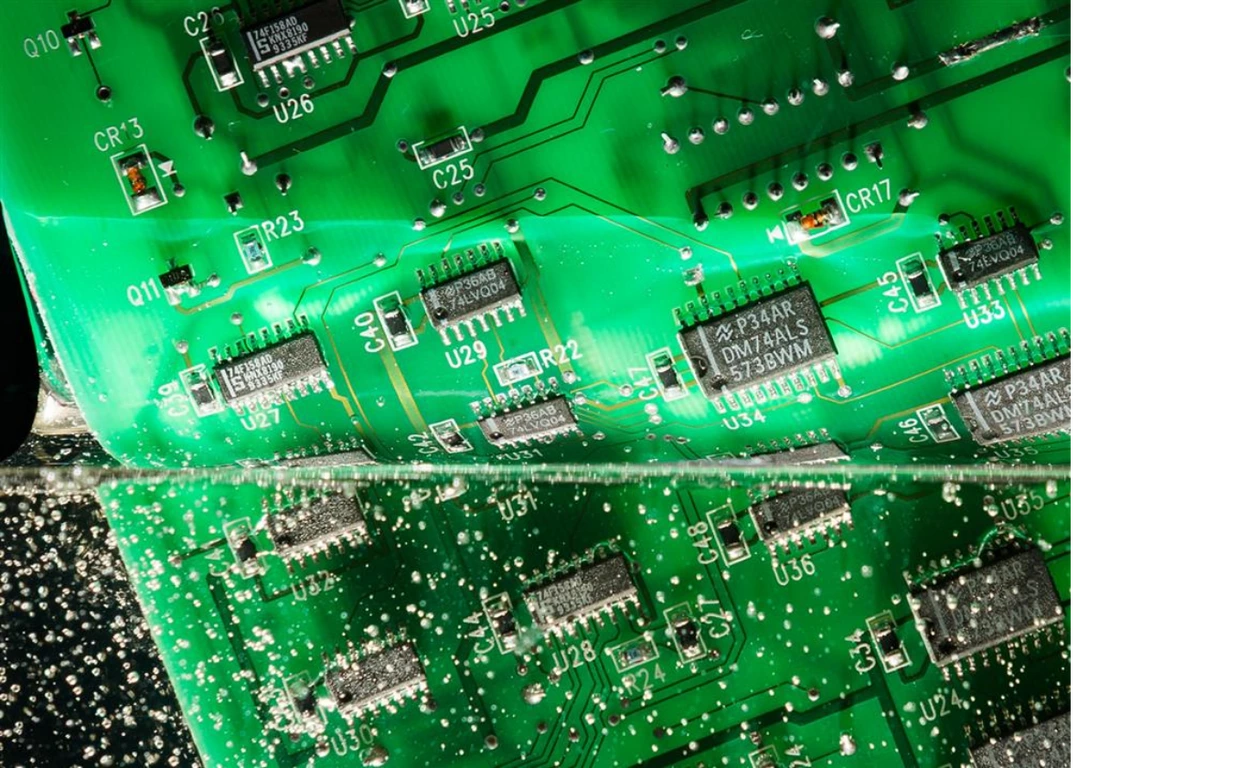

A conformal coating is a 25-200µm (1-8 mils) thick (50µm(1-3 mils) typical) protective membrane (or-coating) that adheres to an assembled PCB by literally ‘conforming’ to its irregular profile. Electrically insulating with good dielectric resistance, it ensures the operational integrity of the assembly

Though no conformal coating could withstand unreasonably prolonged exposure to, for example, an aggressive chemical attack or moisture (due, say, to full immersion), it still excels over other circuit board protection methods such as Potting/Encapsulation and Low pressure molding (LPM) in the matter of:

Besides UV cured Conformal coating that could offer full cure on demand in few seconds, Solvent based or silicone lines product still brings up quicker drying times tackfree time from 30 seconds to a few minutes, ensuring faster production cycles and reduced downtime than potting or melting time of LPM

In the mobile word, Smaller, finer-pitch devices with higher voltage applications needs to optimize the weight and dimension of all the components and specialty materials. Potting and LPM fully encapsulate components with a thick, dense layer of resin, adding significant weight and bulk, while conformal coating could do without much material buildup: a reduction in PCB conductor spacing of over 80%

help eliminate the need for complex, sophisticated enclosures of potting or molding of LPM;Mixing and long staging/curing setup for potting or rigid mold design every time your PCB changes is no longer a concern with conformal coating

Conformal coating, potting/encapsulation/ conformal coating all have its own stage light. Prostech is committed to helping customers choose the most suitable solution tailored to their specific needs. Contact us now!

Automotives

in moderate environmental stress, such as moisture, dust, and temperature fluctuations are Ideal applications in automotives include ECUs, sensor modules and infotainment systems

Consumer Electronics

Consumer electronics especially handheld devices are probably where Conformal coating domains

Industrial Electronics

As industrial automation becomes more advanced and operates under tougher conditions with minimal downtime, control assemblies are increasingly exposed to harsh environments. Common industrial applications needs conformal caoting include control systems, power distribution units, and sensor modules

Aerospaces and defense

Military and aerospace electronics require high reliability, longevity (20-30 years), and resistance to extreme conditions. Conformal coatings protect critical systems like EW, radar, communications, and surveillance while allowing repairs and upgrades. Their durability is vital to prevent failures that could lead to severe operational risks

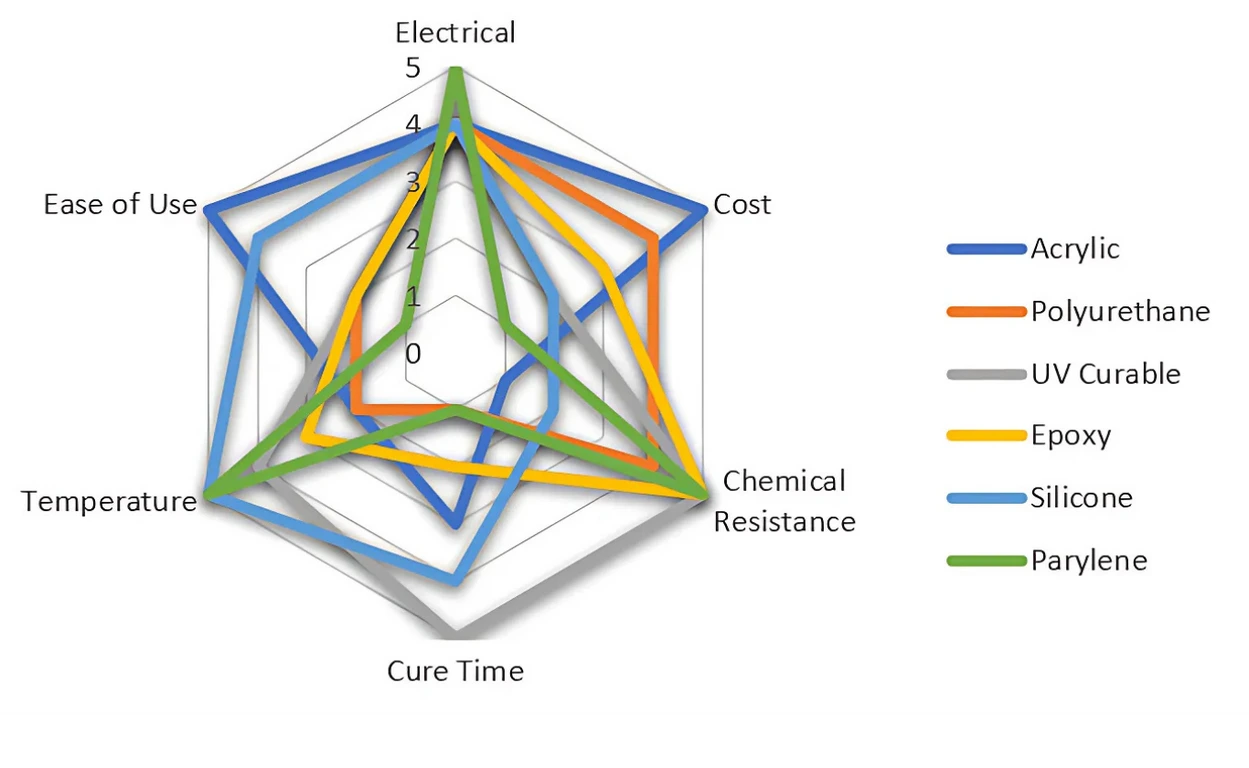

There are currently eight distinct families of conformal coatings, as designated in the IPC-CC-830C Standard: acrylic, polyurethane, silicone, epoxy, UV curable, parylene, ultra-thin and styrenated block-copolymer types.

The first thing to appreciate when selecting a conformal coating is that no perfect solution exists. It is regarded as a working trade-off. A gain in one parameter (for instance thermal resistance or thermal operating range) will inevitably be achieved at the expense of another (poorer salt or chemical resistance, for example)

Choosing the right conformal coating and application process isn’t easy. It therefore pays to work with a supplier that has the experience of solving hundreds of specific coating problems and can give advice on relevant reliability standards and specifications.

Prostech with 1000+ manufacturing customer base worldwide, 100+ database of conformal coating projects from material to process. We are here to support you make one for your own

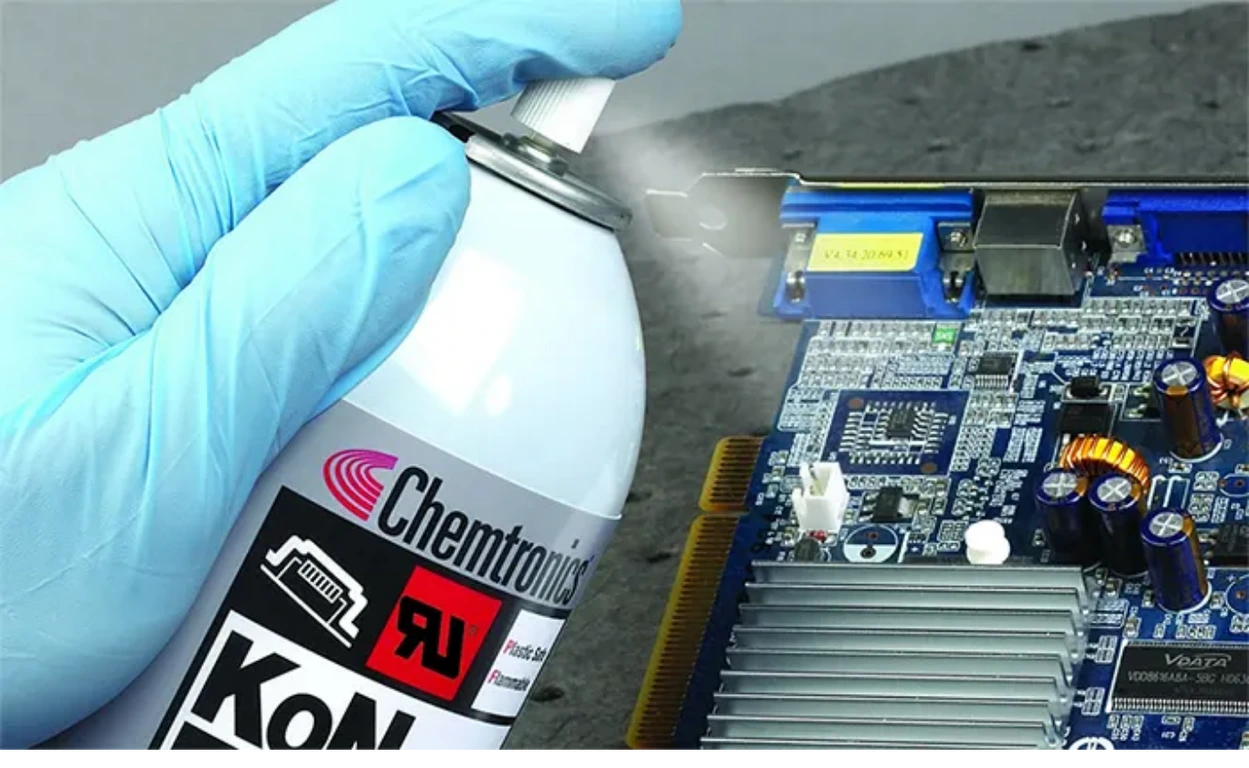

Manual Spray by applicators/ Aerosol

Dipping

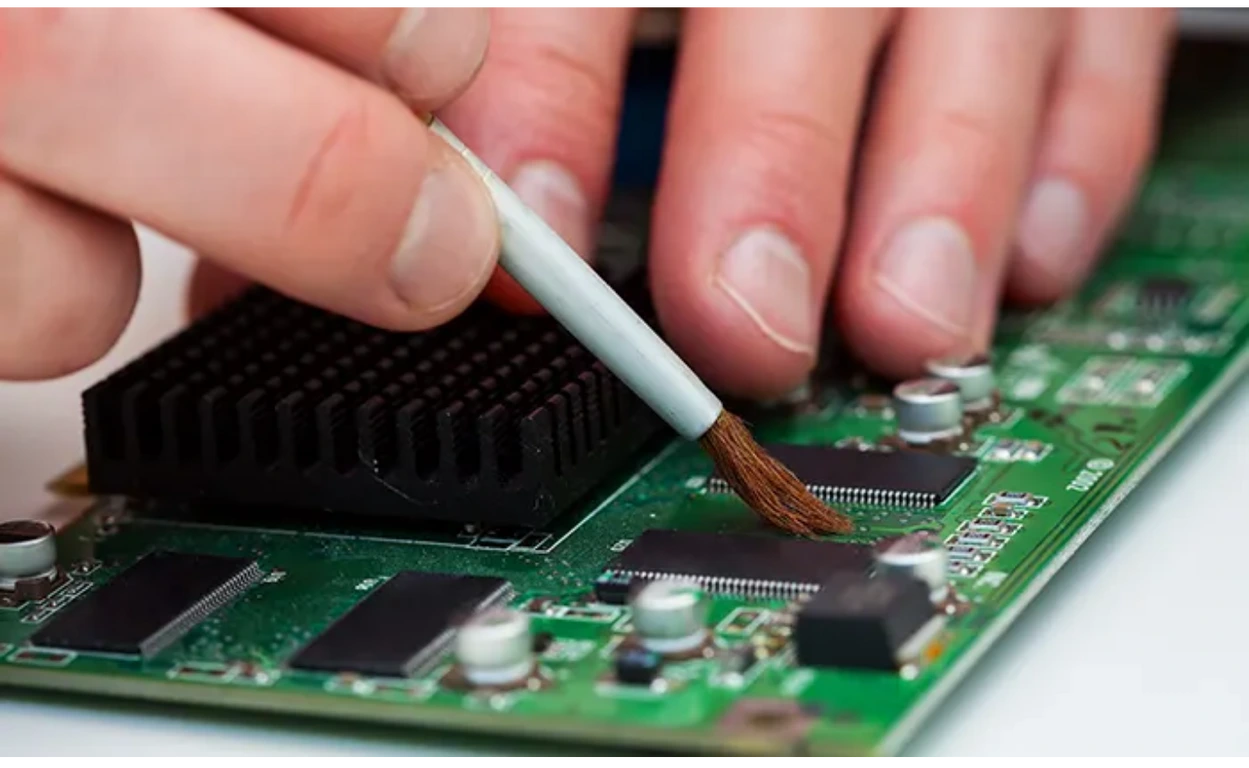

Brusing

Automated coating equipment

|

|

|

Desktop Conformal Coating System

Customizable Inline Conformal Coating System

Why need to add a Conformal Coating for Electrical Insulation purposes? Electrical power rising trends The growing dependence on electrical

When water enters electronics, it leads to an increase in dielectric constant, triggers ionic corrosion, and encourages the development of

Why do electronic devices and PCB need a protective layer? The size, performance, and portability of electronic devices have undergone