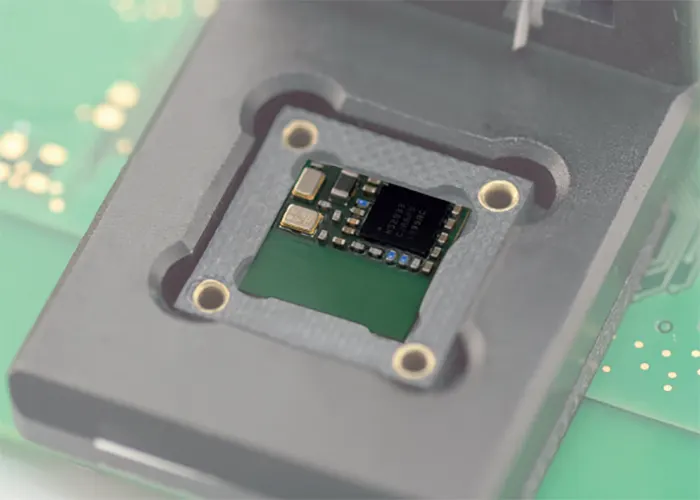

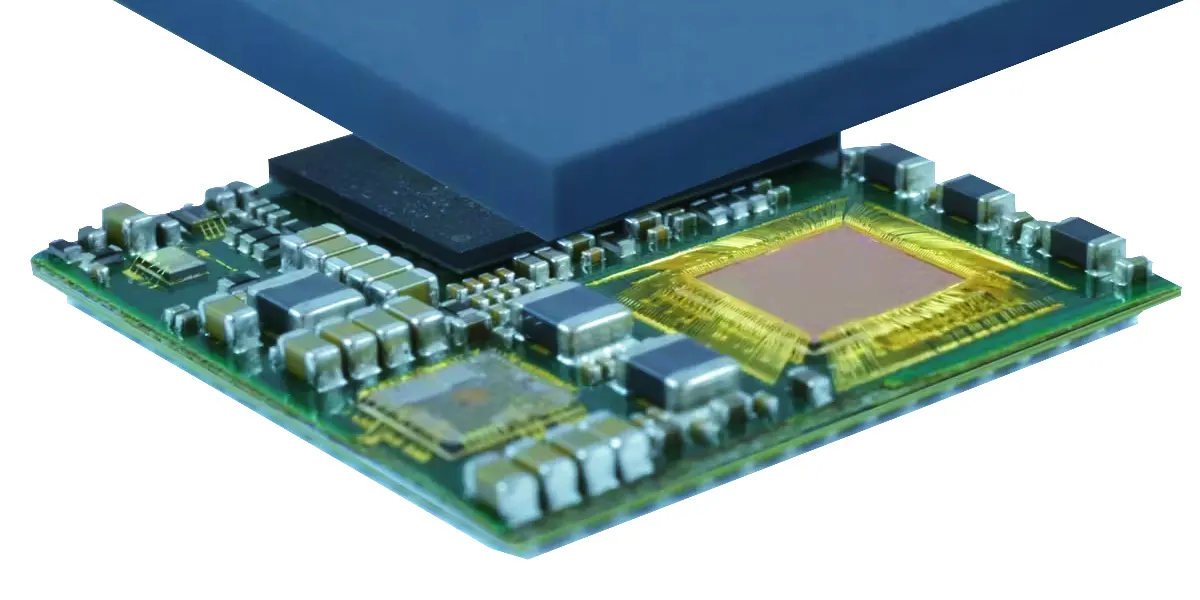

The technique of System in Package (SiP) involves combining various integrated circuits (ICs) and passive components into a unified package, enabling them to function collectively. This differs from the approach of System on Chip (SoC), where the functions of the chips are merged into a single die. This PCB Assembly method was invented to meet the requirements of miniaturization trends of electronic devices.

Despite various advantages, SiP Assembly can bring in longer production times, lower capacities, and higher costs. Prostech’s SiP product line provides a distinctive solution that allows for the simultaneous assembly of passive components and flip-chips with copper pillars, resulting in reduced solder defects, improved efficiency, and enhanced production quality. Take a look at our product line for SiP below