tesa® 61305

tesa® 61305 is a transparent double-sided tape with a PET backing and tackified acrylic adhesive, ideal for bonding cover lenses and touch panels in electronics, offering excellent bonding strength and push-out resistance.

tesa® 61305 Features:

- Superior push-out resistance

- Excellent bonding strength

- Good shock and vibration resistance

- Durable in harsh environments

tesa® 61305 Applications:

- Cover lens mounting in mobile devices

- Touch panel bonding

About Prostech

Prostech Philippines is a one-stop solution provider for specialty materials and equipment across electronics manufacturing, from PCBA to final assembly. Our core material and equipment solutions include:

- PCB Assembly Materials

- Cleaning & Degreaser

- Circuit Board Protection

- Thermal Management Solutions

- EMI Shielding

- General Assembly Adhesives

- Elastomeric Materials

- Process Equipment: Potting & Coating Systems, UV/ Heat Curing, Plasma Treatment, Tape placement automation, and cleaning machines

Technical Added Value to customer

Prostech offers customized material and process equipment solutions with engineering support throughout R&D, production process optimization, and performance validation. Our in-house lab located in Alabang, Muntinlupa is equipped to conduct electronics material testing, application simulation, and adhesive validation, helping customers reduce the need for onsite trials and accelerate implementation.

International Supply Chain Advantage

Regional warehouse hubs across Vietnam, Singapore, Malaysia, and the Philippines ensure cross-border reliable supply. In Philippines PEZA-bonded warehouse located at Lima Industrial Park, Batangas enables Prostech to provide responsive, demand-based delivery and significantly shortens standard lead time for Philippines customers.

Need help selecting the right product or solution?

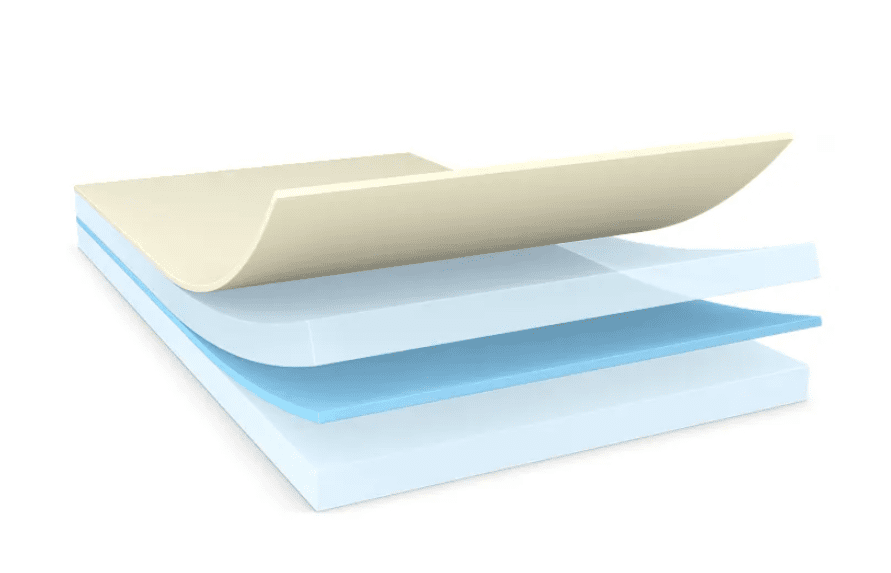

Product Construction

| Adhesive Type | tackified acrylic |

| Backing material | PET film |

| Color | transparent |

| Color of liner | white with tesa logo |

| Liner Type | glassine |

| Thickness of liner | 71 µm |

| Total thickness | 50 µm |

| Weight of liner | 80 g/m² |

Properties / Performance Values

| Elongation at break | 60 % |

| Tensile strength | 8.7 N/cm |

| Temperature resistance short term | 200 °C |

| Temperature resistance long term | 100 °C |

| Tack | medium |

| Static shear resistance at 40°C | good |

| Humidity resistance | very good |

| Ageing resistance (UV) | very good |

Adhesion to Values

| Adhesion to ABS (initial) | 8 N/cm |

| Adhesion to ABS (after 14 days) | 8.5 N/cm |

| Adhesion to Glass (initial) | 12.4 N/cm |

| Adhesion to Glass (after 14 days) | 12.7 N/cm |

| Adhesion to PMMA (initial) | 11.5 N/cm |

| Adhesion to PMMA (after 14 days) | 12 N/cm |

| Adhesion to Steel (initial) | 10.3 N/cm |

| Adhesion to Steel (after 14 days) | 12.9 N/cm |