Product Introduction

tesa® 8851 is an ultra-thin, double-sided non-woven tape, engineered with exceptional temperature resistance, making it suitable for micro-speaker dome and FPC mounting applications.

tesa® 8851 Features:

- Ultra-thin, double-sided non-woven tape for precision applications

- Stable holding power and peel strength after high-temperature processes

- High tensile strength and excellent die-cutting properties

- Minimal oozing due to special backing

- Conforms to RoHS regulations

tesa® 8851 Applications:

- Micro-speaker dome mounting

- FPC mounting applications

- Electronic component mounting in high-temperature environments

About Prostech

Prostech Philippines is a one-stop solution provider for specialty materials and equipment across electronics manufacturing, from PCBA to final assembly. Our core material and equipment solutions include:

- PCB Assembly Materials

- Cleaning & Degreaser

- Circuit Board Protection

- Thermal Management Solutions

- EMI Shielding

- General Assembly Adhesives

- Elastomeric Materials

- Process Equipment: Potting & Coating Systems, UV/ Heat Curing, Plasma Treatment, Tape placement automation, and cleaning machines

Technical Added Value to customer

Prostech offers customized material and process equipment solutions with engineering support throughout R&D, production process optimization, and performance validation. Our in-house lab located in Alabang, Muntinlupa is equipped to conduct electronics material testing, application simulation, and adhesive validation, helping customers reduce the need for onsite trials and accelerate implementation.

International Supply Chain Advantage

Regional warehouse hubs across Vietnam, Singapore, Malaysia, and the Philippines ensure cross-border reliable supply. In Philippines PEZA-bonded warehouse located at Lima Industrial Park, Batangas enables Prostech to provide responsive, demand-based delivery and significantly shortens standard lead time for Philippines customers.

Need help selecting the right product or solution?

Typical Properties

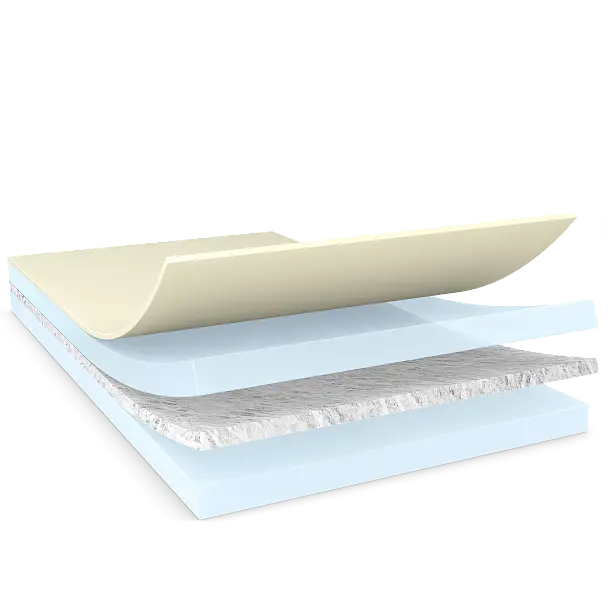

Product Construction

| Backing material | ultra thin non-woven |

| Color | translucent |

| Color of liner | white/red logo |

| Thickness of liner | 2.8 mils 71 µm |

| Total thickness | 1.18 mils 30 µm |

| Type of adhesive | type: tackified acrylic |

| Weight of liner | 116.63 lbs/in² 82 g/m² |

Adhesion to Values

| Adhesion to ABS (initial) | 1.94 lbs/in 3.4 N/cm |

| Adhesion to ABS (after 14 days) | 2.63 lbs/in 4.6 N/cm |

| Adhesion to Aluminium (initial) | 2 lbs/in 3.5 N/cm |

| Adhesion to Aluminium (after 14 days) | 3.14 lbs/in 5.5 N/cm |

| Adhesion to PC (initial) | 2.11 lbs/in 3.7 N/cm |

| Adhesion to PC (after 14 days) | 2.86 lbs/in 5 N/cm |

| Adhesion to PET (initial) | 2.28 lbs/in 4 N/cm |

| Adhesion to PET (after 14 days) | 2.51 lbs/in 4.4 N/cm |

| Adhesion to PI (initial) | 2.46 lbs/in 4.3 N/cm |

| Adhesion to PI (after 14 days) | 2.51 lbs/in 4.4 N/cm |

| Adhesion to Steel (initial) | 2.28 lbs/in 4 N/cm |

| Adhesion to Steel (after 14 days) | 3.14 lbs/in 5.5 N/cm |