Thermally Management role in durability and performance of Battery Pack

A basic principle of physics is that heat can be transferred in three ways: radiation (the outward propagation of infrared waves), convection (the movement of molecules in liquids or gasses from hot areas to colder areas), and conduction (transfer of energy via direct contact with an adjoining body). Conduction is the most effective means of transferring heat, but currently, some leading car manufacturers use EV battery pack designs that employ radiant methods of heat dissipation. This can result in poor temperature distribution, hot spots and EVs that are limited in performance.

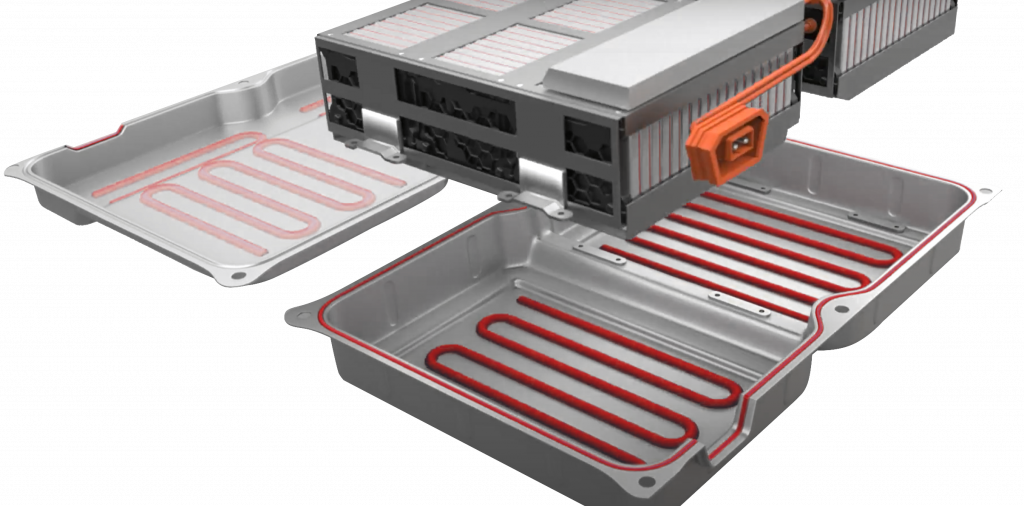

Many EV manufacturers are turning to liquid-cooling methods for thermal management. For a conductive liquid-cooled system to function effectively, the battery pack must be in close contact with a cooling plate. To the naked eye, surfaces within the battery assembly appear to be quite smooth and in perfect contact. At the microscopic level, however, both surfaces have peaks and valleys that create roughness, entrap air and prevent ideal contact.

Battery pack designers use thermal interface materials (TIMs) to displace the air and fill in gaps between the two substrates. Traditionally, thermal pads have been used as a TIM, but thermally conductive liquid-dispensed gap fillers are growing in popularity, due to lower costs and higher performance.

Thermal management in EVs, ensuring batteries do not overheat, is a critical focus for vehicle safety and lifetime battery performance. End-consumer range anxiety can be specifically addressed with technology solutions that ensure higher energy density and fast charging, without increased stress on the battery system. For these thermal management requirements, a broad range of thermal gap fillers and other thermal interface materials (e.g. thermal gap pads, thermally conductive adhesives) is used to improve battery pack performance and reliability.

Challenges

These challenges come from lots of roots:

- The lower case of the battery pack contains complex construction of multiple battery modules, controllers, and cooling systems.

- The battery pack is made from a wide variety of substrates: steel, aluminum, composites without any typical pretreatment such as e-coat, etc

- The materials are easily affected by outside elements: water, dust, road salt, and automotive fluids.

- The packing box takes charge of protecting inside battery from vibration and shock during operation.

Thermal Management Solutions

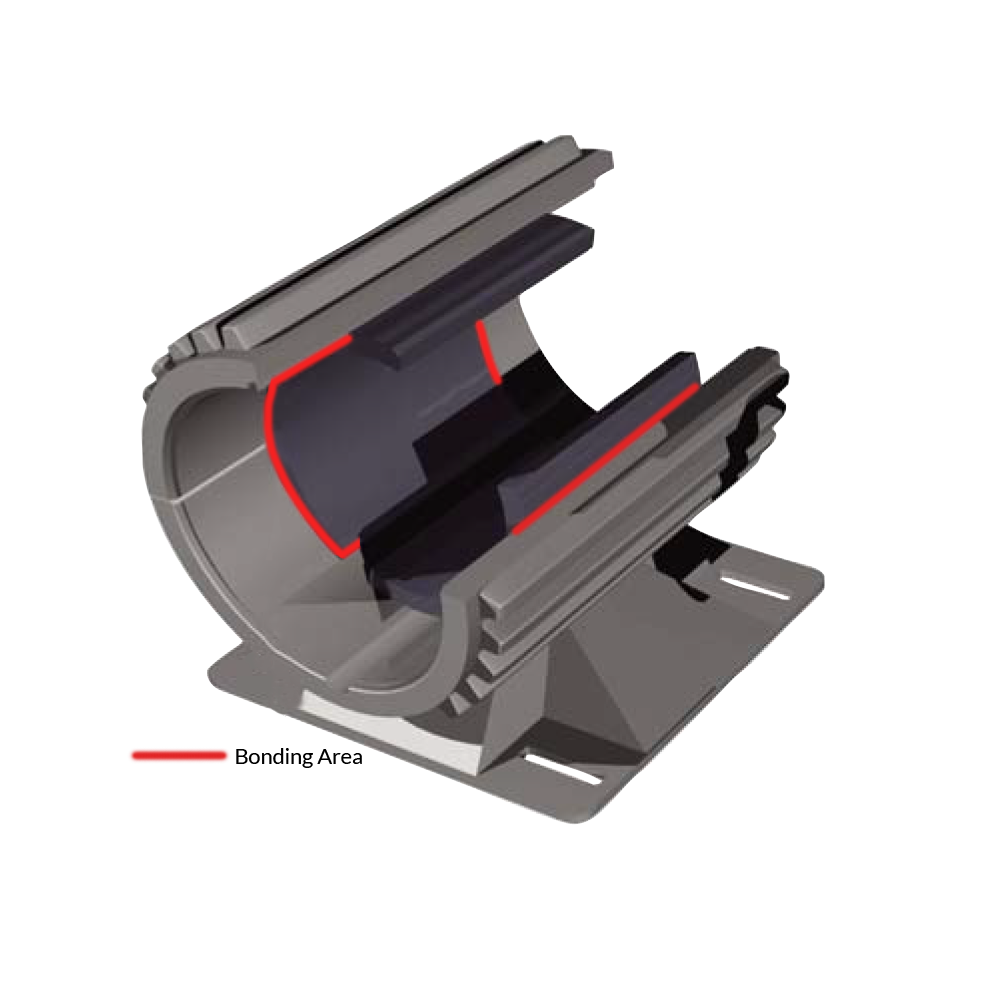

1. Thermally Conductive Gap FillerMaintaining resiliency for consistent cooling performance reliable elastomeric springs to maintain close contact between the cooling plate and the battery, ensuring performances.

|

|

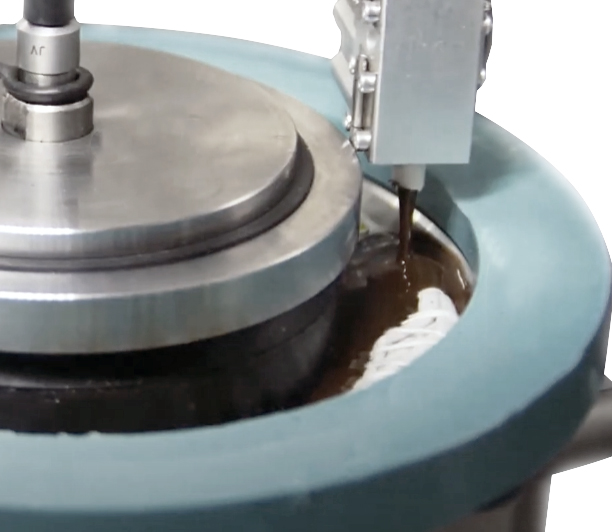

2. 2K Dispensing SystemCustomizable & Modular Dispensing System for metalized (thermally conductive) adhesive.

|

|

Which TIMs is the best choice?

Each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+84) 984 695 398

Email: gluexpert@prostech.ph