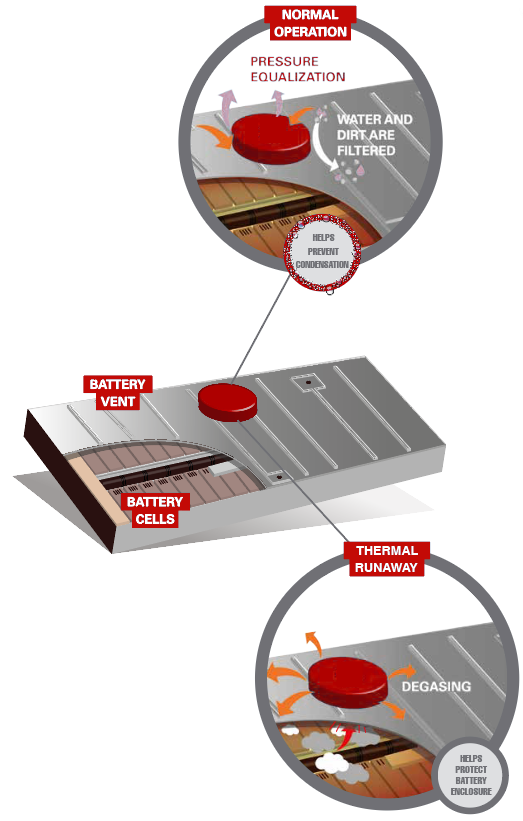

Dual-stage vents help PROTECT automotive battery packs and SUPPORT BATTERY LIFE and RELIABILITY with 4 KEY FUNCTIONS

Water, dust, debris, and other elements exposing challenges of EV Battery

Cell chemistries, thermal dynamics, vehicle packaging, and even weather present challenges for optimizing electric vehicle battery functional safety.

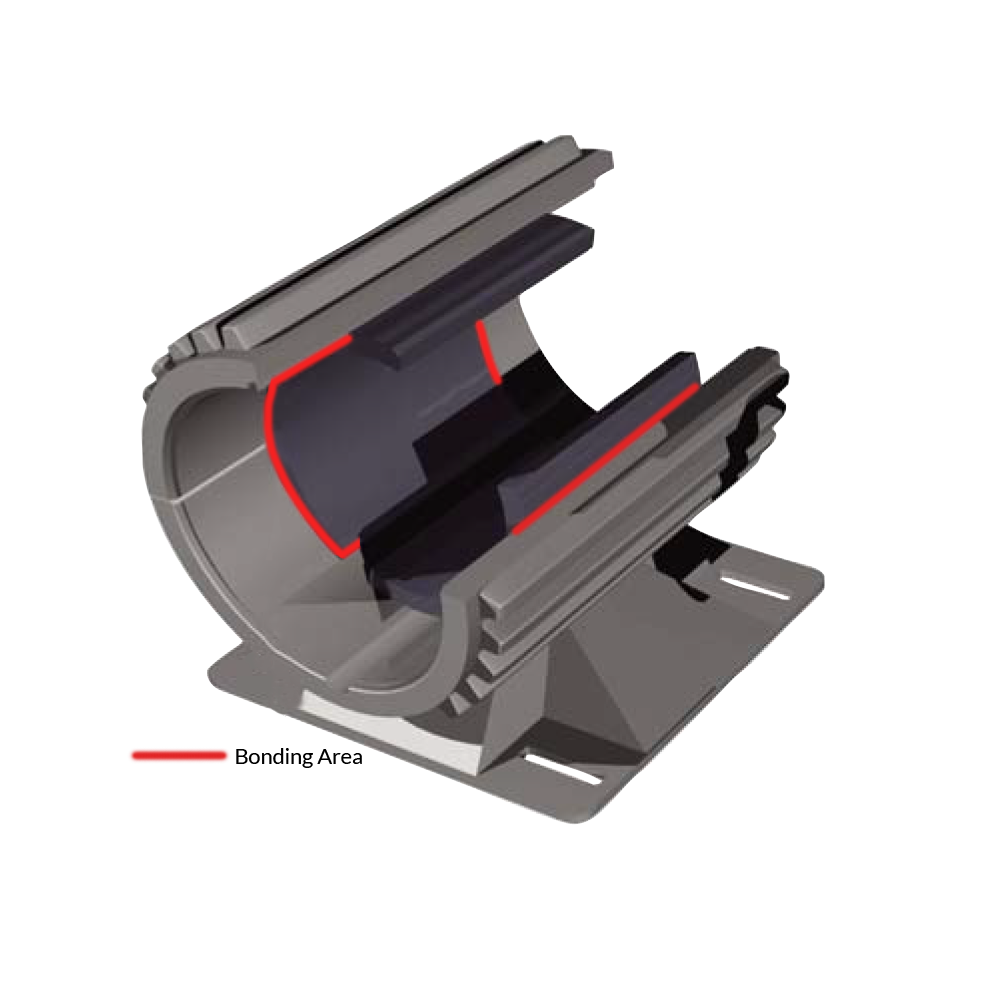

Batteries for electric vehicles (EVs) need protection from harsh external conditions. Generally located on the underside of the vehicle, EV battery enclosures protect the cells from exposure to water, dust, debris, and other elements. Like other enclosures, EV battery enclosures also undergo temperature and pressure changes that can lead to problems without proper venting. But EV batteries present unique venting challenges including potentially dangerous thermal runaway conditions. Considering these challenges, integration of design, manufacturing, installation, and testing are crucial to optimal EV battery venting performance.

Numerous components in an EV require venting. Lighting, horns, electronics, powertrain, and other components all experience temperature changes resulting from weather conditions, moisture, or heat from electronic circuits. These temperature fluctuations produce pressure changes inside the components. Changes in altitude can also trigger pressure changes.

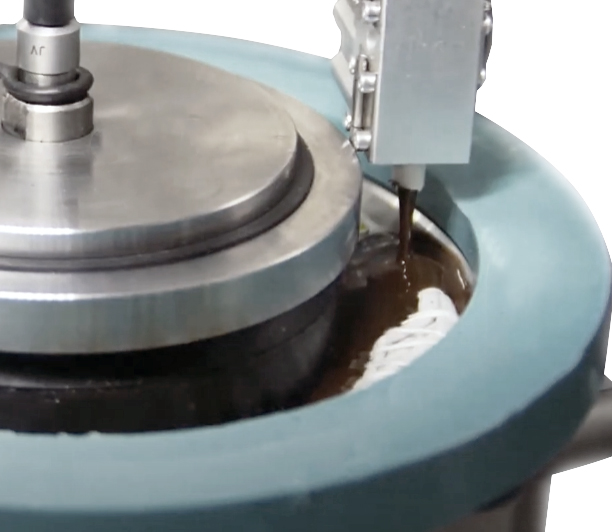

Expanded polytetrafluoroethylene (ePTFE) membranes have proven effective in venting EV enclosures and providing pressure equalization. This material allows gases to flow in and out of the enclosure but helps prevent liquid and particle contaminants from entering the enclosure.

Along with exposure to the various elements experienced by other automotive components, battery packs present additional challenges due to their location, size, and chemical makeup. Packs located on the undersides of vehicles can be exposed to water fording or submersion as a vehicle traverses standing water. Roadway water may include salt and other corrosive chemicals. Car washes can expose vehicles to high-pressure sprays of varying temperatures. Dust, debris, and vibration can also impact the battery pack.

The size of EV battery packs also presents challenges. Weighing up to 2,000 pounds (907 kg), the packs contain hundreds — sometimes thousands — of cells, with large air volumes that can exert forces on the enclosures as pressures increase. This creates significant venting needs to account for differential pressure due to altitude or temperature change.

|

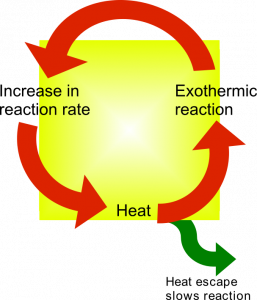

Thermal Runaway DamagePerhaps the biggest challenge with EV battery packs is the potential for thermal runaway. If lithium-ion battery cells are damaged by puncturing, overcharging, manufacturing defect, or other causes, they can release gas and heat. This can trigger other cells to decompose, leading to a thermal runaway condition where rapidly increasing temperatures and pressures released by cells exceed the venting capability of ePTFE membrane vent. At this point, the vent is unable to allow gases to escape fast enough and additional pressure relief is needed to avoid rupturing the battery pack enclosure, which is typically made of lightweight materials to conserve weight. |

Function of Venting Film

|

|

How does it work?

Properly designed venting systems provide protection from contaminants along with pressure equalization during normal operating conditions, helping lead to longer-lasting enclosures and battery life cycles. In the rare case of thermal runaway, the venting system must also be capable of providing immediate pressure relief, helping avoid component failure or propagation to additional cells..

The first stage of dual-stage battery venting is pressure equalization. A porous ePTFE membrane allows air and other gases to move in and out of the battery pack. Pressure equalization is needed during normal vehicle operation, due to changes in altitude and temperature.

In the case of rapid pressure and heat buildup, the second stage helps maintain internal enclosure pressures by allowing gases to escape by either bypassing the membrane with the umbrella flex or bursting the membrane

ePTFE Venting Film Solution

|

BENEFITS:

|

PROSTECH ePTFE membrane products are available in multiple widths, thicknesses, and densities, allowing designers to dial in their airflow, particulate and liquid ingress protection needs. Made from only PTFE resin, these products can also be sterilized for use in highly clean applications.

Please contact for more information:

Hotline: (+84) 984 695 398

Email: gluexpert@prostech.ph