Product Introduction

VYLOSHOT® GM-950-RF4 is a gray, high-performance low-pressure molding material engineered for advanced electronic encapsulation applications that require robust mechanical strength and excellent heat resistance. It features a high melting point of 182℃ and a very high Shore A hardness of 94, providing superior durability and dimensional stability. Its high melt viscosity ensures stable performance during demanding molding cycles. This material offers strong electrical insulation and a low moisture content, making it an excellent choice for protecting sensitive electronic components in harsh operating environments where structural integrity and thermal performance are critical.

VYLOSHOT® GM-950-RF4 Features

- Utilizes a low-pressure molding process to safely encapsulate delicate components.

- Allows for rapid processing cycles and aids in the design of miniaturized electronics.

- Offers high hardness and dimensional stability with a Shore A hardness of 94.

- Provides excellent heat resistance with a high melting point of 182℃.

- Delivers a high tensile modulus of 70 MPa for robust mechanical strength.

- Ensures strong electrical insulation with a volume resistivity of 3.00 × 1012 Ω·cm.

- Features a high melt viscosity of 890 dPa·s at 220°C for stable molding.

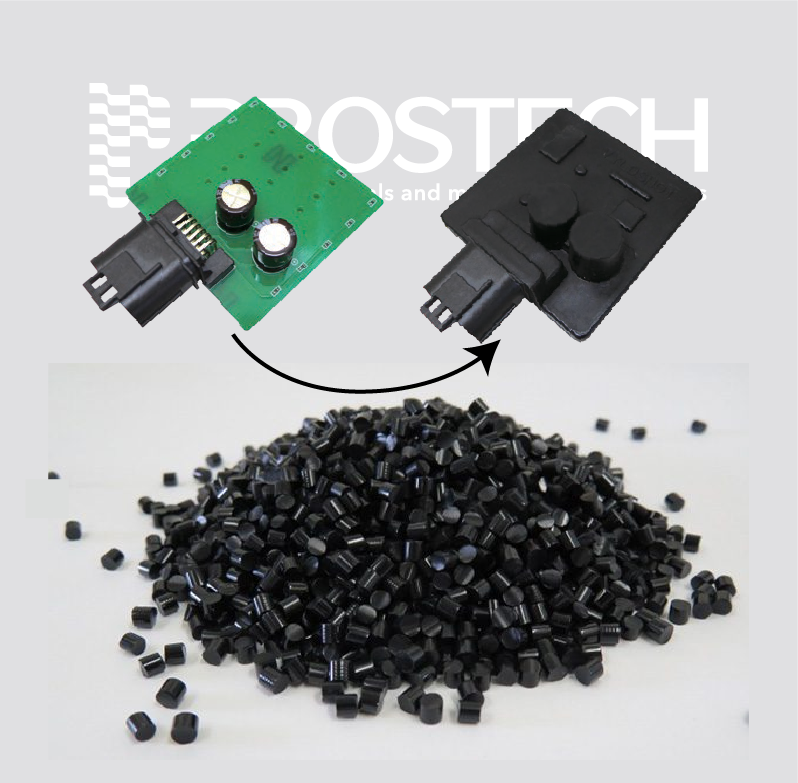

VYLOSHOT® GM-950-RF4 Applications

- Used for encapsulating sensors such as seat belt, tire pressure, gas emission, door, weight, torque, and speed sensors.

- Provides protection for Electronic Control Units (ECUs), including power window controls.

- Ideal for EV/PHV plug-in charging devices, camera modules, and wire harness assemblies.

About Prostech

Prostech Philippines is a one-stop solution provider for specialty materials and equipment across electronics manufacturing, from PCBA to final assembly. Our core material and equipment solutions include:

- PCB Assembly Materials

- Cleaning & Degreaser

- Circuit Board Protection

- Thermal Management Solutions

- EMI Shielding

- General Assembly Adhesives

- Elastomeric Materials

- Process Equipment: Potting & Coating Systems, UV/ Heat Curing, Plasma Treatment, Tape placement automation, and cleaning machines

Technical Added Value to customer

Prostech offers customized material and process equipment solutions with engineering support throughout R&D, production process optimization, and performance validation. Our in-house lab located in Alabang, Muntinlupa is equipped to conduct electronics material testing, application simulation, and adhesive validation, helping customers reduce the need for onsite trials and accelerate implementation.

International Supply Chain Advantage

Regional warehouse hubs across Vietnam, Singapore, Malaysia, and the Philippines ensure cross-border reliable supply. In Philippines PEZA-bonded warehouse located at Lima Industrial Park, Batangas enables Prostech to provide responsive, demand-based delivery and significantly shortens standard lead time for Philippines customers.

Need help selecting the right product or solution?

Typical Properties

| Property | Value |

|---|---|

| Color | Gray |

| Specific gravity | 1.19 |

| Melting point | 182℃ |

| Glass transition temp. | -70℃ |

| Melt viscosity (220°C) | 890dPa·s |

| Equilibrium moisture content | 0.3% |

| Hardness (Shore A) | 94 |

| Tensile strength | 6MPa |

| Tensile elongation | 130% |

| Tensile modulus | 70MPa |

| Volume resistivity (20°C) | 3.00E+12Ω·cm |