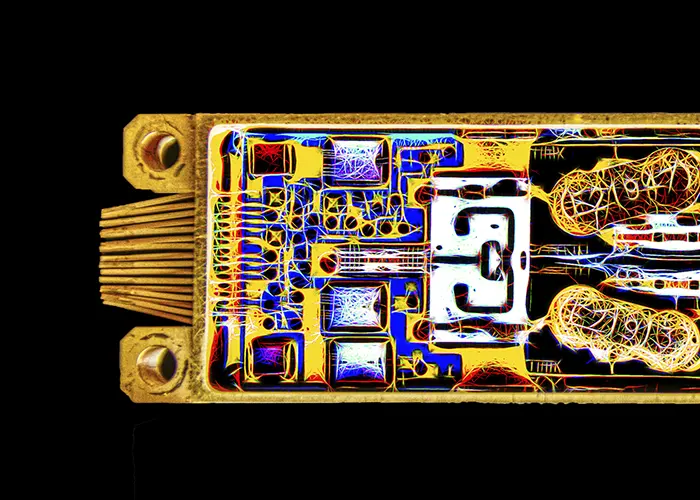

What is Conformal Coating?

Conformal coating serves as a safeguarding layer that is applied to electronic circuit boards and components to protect them from environmental elements such as moisture, dust, chemicals, and temperature fluctuations. It is a slim, insulating film that conforms to the shape of the coated surface, creating a barrier between the electronic components and their surroundings. By preventing corrosion, insulation breakdown, and short circuits, conformal coatings enhance the dependability and durability of electronic devices in a range of industries, including automotive, aerospace, consumer electronics, and industrial applications.

Type of Conformal Coating

Conformal coatings are available in various forms, including solvent-based, water-based, and high or 100 solids such as silicones and UV-curable. These coatings differ in their physical properties.

Conformal coatings employ a range of standard chemistries such as acrylics, urethanes, silicones, synthetic rubbers, and UV-curable acrylate urethanes. The physical properties of each chemistry are tailored to specific conditions and end-uses.

For instance, while silicones offer superior temperature resistance, synthetic rubbers and UV curable are better suited to high-humidity environments. This understanding of the properties of different conformal coating chemistries is critical for successful application.

How to choose a suitable conformal coating product?

There are huge ranges of criteria that need to be considered when choosing a conformal coating layer. And It is essential to understand that there is no flawless solution when it comes to choosing a conformal coating.

Consequently, it is imperative to acknowledge that the effectiveness of any conformal coating is essentially a balancing act. Enhancing a specific feature such as thermal resistance or operating range will inevitably result in a compromise in another aspect, such as diminished salt or chemical resistance.

Prostech can list down some considerations when choosing a conformal coating but for more details, you need more advice from Prostech experts. Contact us here.

Some considerations when choosing a conformal coating products

The chemical base of conformal coating

- Acrylics Conformal Coating

- Urethanes Conformal Coating

- UV Cure Conformal Coating

- Synthetic Rubber & Silicones Conformal Coating

- Epoxy Conformal Coating

Qualifications

are there any compulsory qualifications in your industry that you need to follow?

- MIL-I-46058C – Military Qualification Certificated Conformal Coating

- IPC CC-830B – commercial alternative to the MIL-I-4608C

- UL746E & UL94 – flammable material qualification certification related.

Liquid Properties

available as an aerosol, solid content, viscosity, flash point, VOC, drying time & shelf life are all need to be considered.

Physical Properties

Continuous Use Operating Range, Thermal Shock, Glass Transition Temperature, CTE, Dielectric Constant

Electrical Properties

Dissipation Factor, Dielectric Withstand Voltage V (1 minute), Insulation Resistance, Moisture Insulation Resistance, Resistance to chemicals and solvents, Recommended Thinner (Dip & Brush/Spray), Recommended Stripper.

For urgent support on samples, testing, or technical consultant in Philippines, please contact our local representative: