The electronic market is continually moving towards higher power densities. As a result, the demand for cooling is increasing. Focus must be put on the whole thermal management chain, from the component to be cooled to the ambient. Thermal interface materials are used to efficiently transfer heat between two mating surfaces or in some cases across larger gaps. There are several different thermal interface materials with various application areas, advantages, and disadvantages. This article aimed to evaluate the thermal and mechanical properties of thermal conductive graphite.

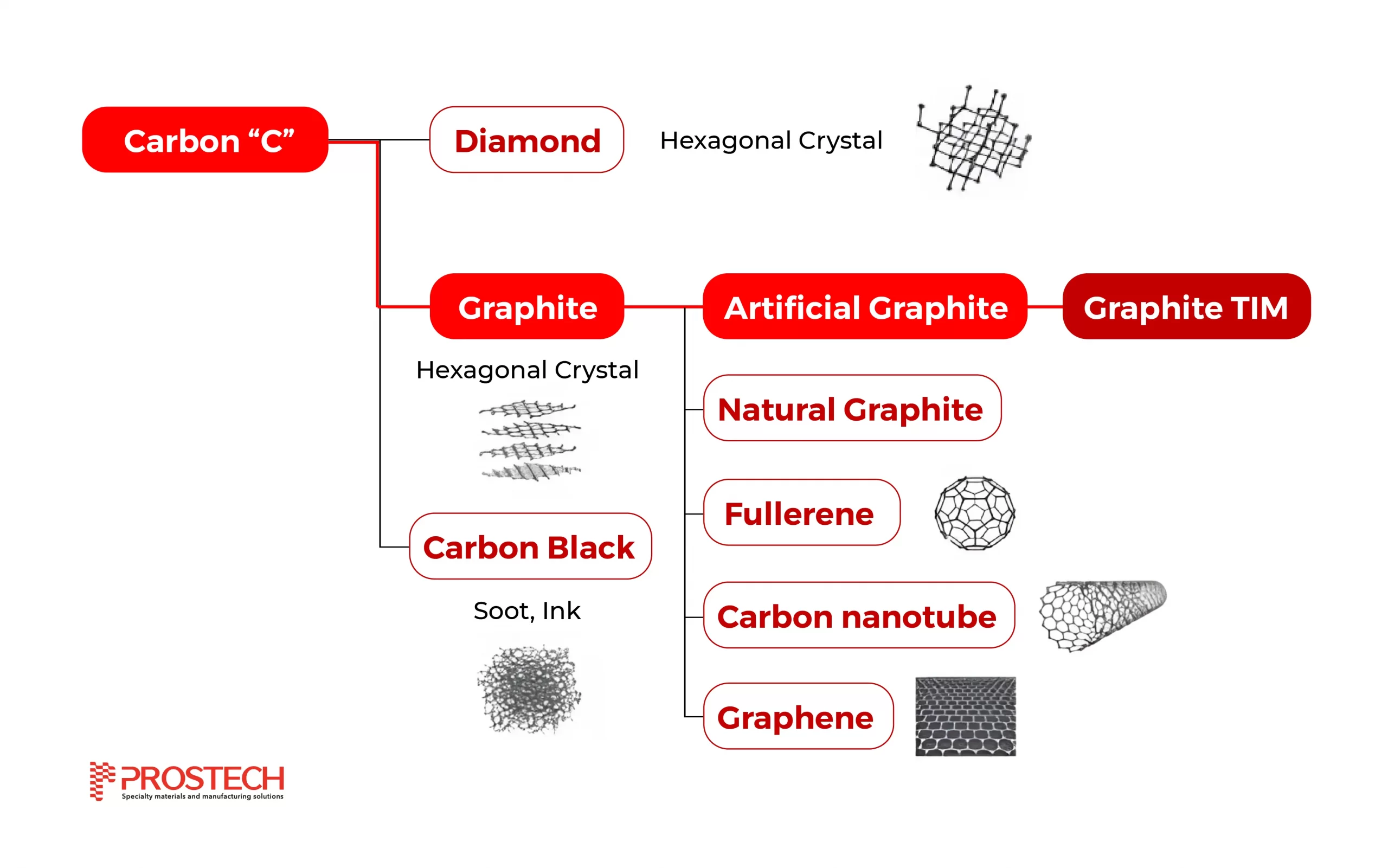

1/ What is thermal conductive graphite?

Thermally Conductive Graphite is a thermal interface material with high thermal conductivity and a thin graphite film structure (thickness measured in microns).

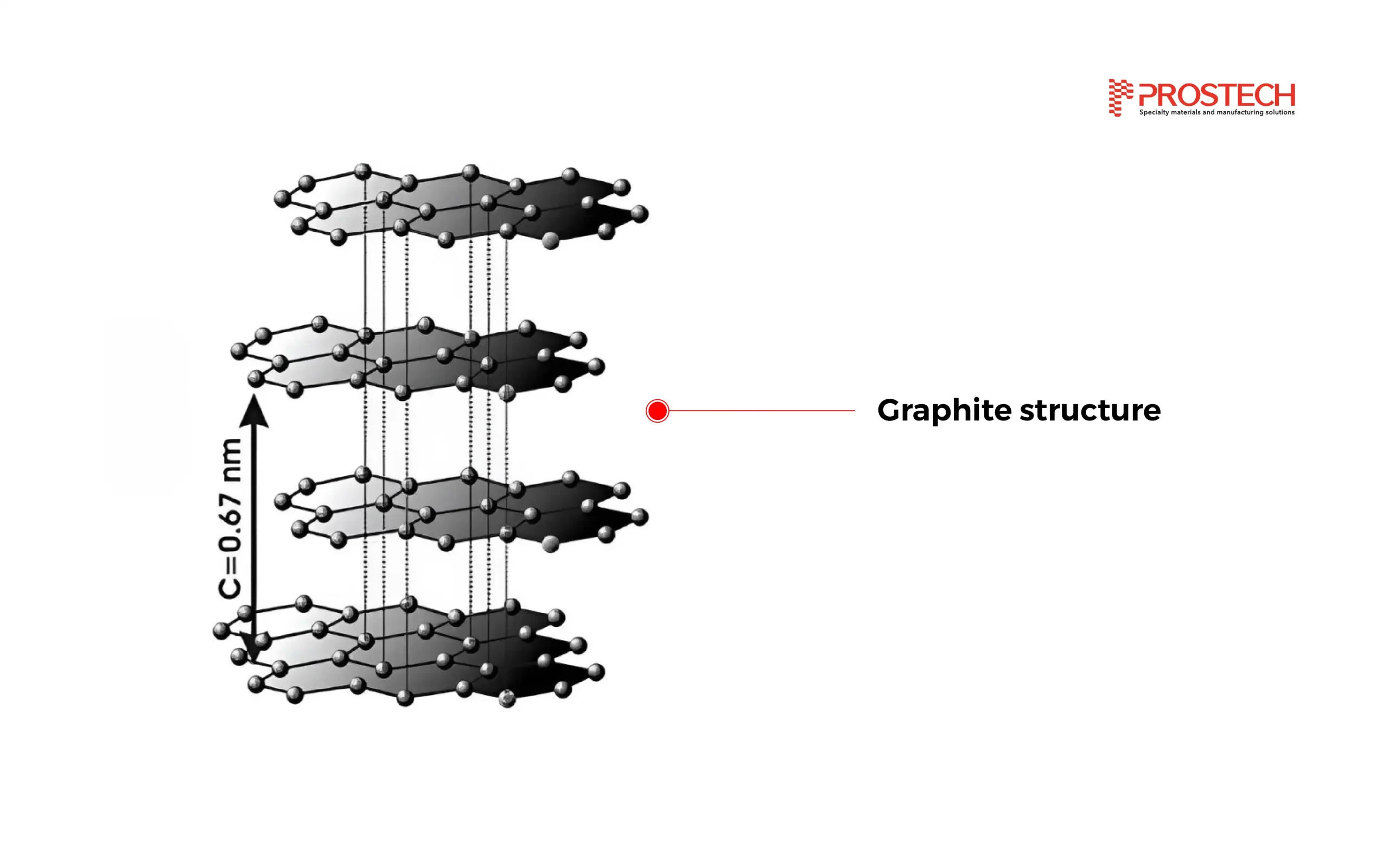

Graphite is formed of a layered structure with strong covalent bonds within the layers, and weak van der Waals bonds connecting the layers.

Graphite has anisotropic physical properties. The thermal conductivity is in the magnitude of 1800 W/(m∙K) in the plane but only around 5~20 W/(m∙K) through the thickness, making it a good heat spreader and possibly also an insulator.

Thermally Conductive Graphite is created from a high-temperature sintering process, heating a polymer film to its decomposition temperature in a vacuum and allowing it to carbonize and then graphitize until ultimately left with a highly oriented graphite material. Graphite’s sheet-like crystals known as graphene are stacked on top of each other, allowing for extremely high in-plane thermal conductivity (x-y direction) compared to its through-plane thermal conductivity (z-direction).

2/ Advantages of Thermal conductive graphite

With the rapidly growing demands of data consumption and communication as well as the shrinking size of modern-day devices, especially in the emerging world of 5G and the Internet of Things (IoT), the need for improved thermal management and heat dissipation solutions is becoming more and more urgent. To address these concerns, Thermally Conductive Graphite offers up to five times the thermal conductivity of copper, at only a fraction of the weight. There are numerous advantages, especially when compared to its metallic counterparts:

- Low thermal resistance: Graphite TIM provides as good low thermal resistance as grease

- High reliability: Reliable performance from -40°C to 400°C. Graphite TIM maintains high reliability for a long period compared to grease because of its property of hardly changing thermal resistance.

- High thermal conductivity: up to 1800 W/(m∙K) in the plane and around 15 W/(m∙K) through the thickness

- Lightweight

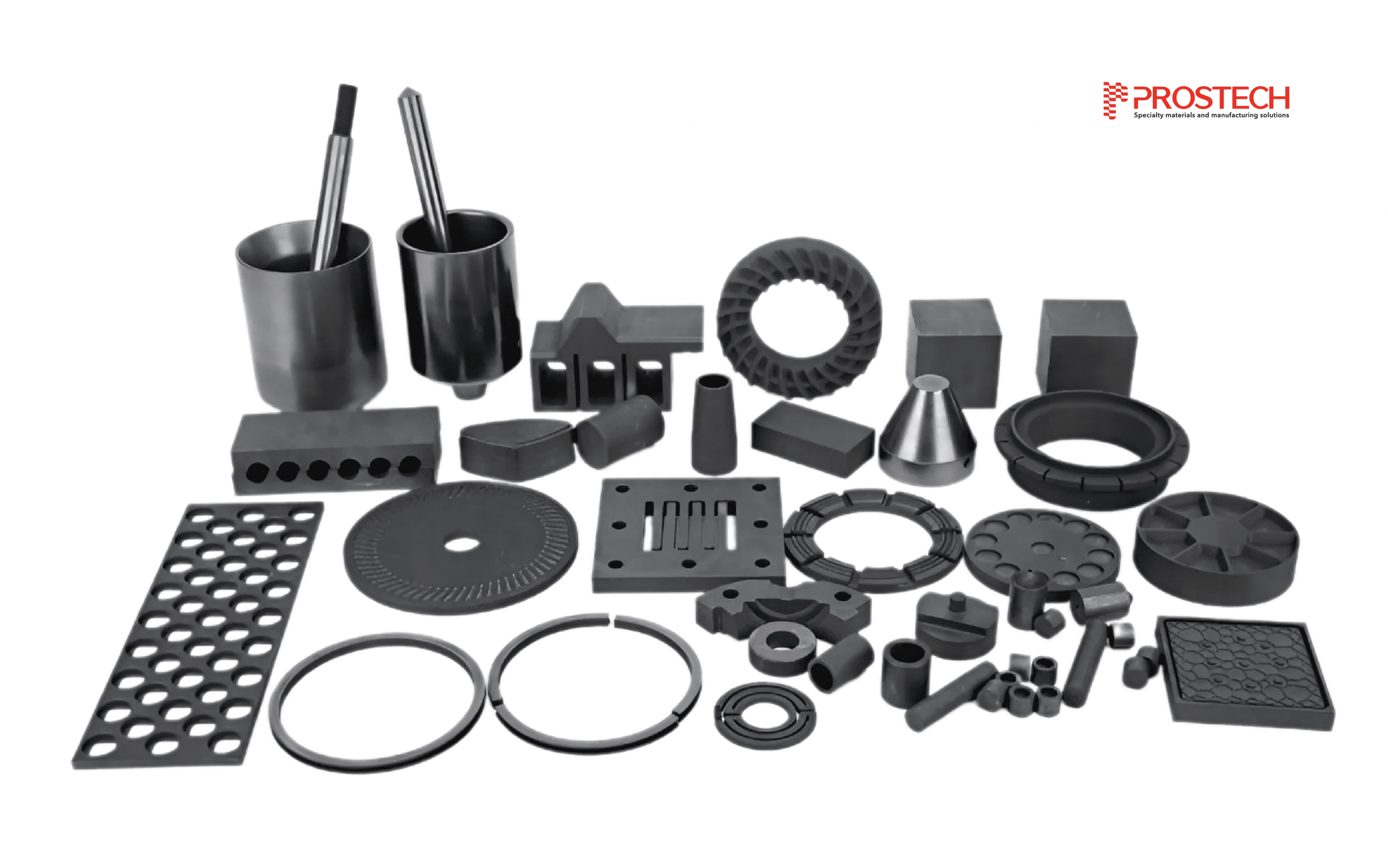

- Available in custom shapes

- Offered with adhesives for fast installation (peel-and-stick attachment).

- EMI shielding and absorbing to protect sensitive electronic parts.

- Offers excellent flexibility (withstands repeated bending).

Besides the excellent features of thermal conductive graphite, there are some problems when applying this material in your production due to many reasons such as application technique, and operational environment, … Prostech offers total solutions from choosing suitable products to applying automation processes for your manufacture. Contact us for more information and valuable consultation from our qualified experts

3/ Application of Thermal conductive graphite

Thermally Conductive Graphite offers thermal conductivity up to 1800 W/m-K and is very thin, which allows for easy attachment to a variety of heat sinks or component surfaces. The high thermal conductivity graphite can easily be used for thermal management in electronics (adhesives available for easier application) or other space-limiting areas. The material is flexible and can be used in a wide range of temperatures.

Automotive

Thermal conductive graphite offers a unique combination of high thermal conductivity, thin profile, lightweight construction, and adaptability, making it a valuable material for efficient heat management in various automotive applications such as engine management, electronic suspension, braking systems, communication and multimedia systems, and vehicle lighting and controls, or in EV application like battery thermal management and cooling solutions. It also offers thermal spreading for important LIDAR and infrared cameras and sensors in semi-autonomous vehicles.

Display

TC graphite can be considered for any display application where heat generation can negatively impact performance or lifespan (e.g., high-brightness displays, displays in hot environments); thin and lightweight designs are desired (e.g., mobile devices, TVs with slim bezels); conformal contact with uneven display surfaces is needed for effective heat transfer (e.g., curved displays, foldable displays).

Aerospace and Medical devices

Flexible graphite heat spreaders offer superior thermal capabilities for critical electronics and sensors. EMI shielding protects sensitive applications.

Consumer Electronics

Thermally Conductive Graphite is an excellent thermal interface material and can be used for several applications, including mobile devices, communication base stations, laptops, tablets, computer servers, gaming stations, memory modules, semiconductors, CPUs, GPUS, printed circuit boards, high power batteries, and solar power systems.

4/ Prostech’s solution

There is no doubt about the excellence of the graphite sheet thermal interface material which is why their production and usage have insanely increased over the past years. They enhance the conductivity and composition of the entire system through these and all in all, these are best for enhancing the overall working of the system they are a part of.

With a comprehensive range of chemistry platforms, Prostech offers the most application flexibility for thermal conductive graphite solutions such as:

|

|

|

|

Prostech ensures optimal performance and reliability in these critical materials solutions through advanced technology and meticulous attention to detail. With a focus on improving efficiency and improving the quality of life, Prostech’s thermal conductive graphite solutions will bring you great experiences when using our products.

—————————————–

For more information, contact us to talk with our glue experts: