Choosing the right adhesive can be a complex decision that requires balancing the demands of production processes with the performance needs of the final product. In the medical field, this choice is even more critical due to strict safety and performance standards. For example, one of the key requirements for medical adhesives is that they must be safe to use on or in the body, which is known as biocompatibility. In recent years, there’s been a lot of progress in medical adhesives, particularly in the use of UV-cured adhesives.

What is UV adhesive?

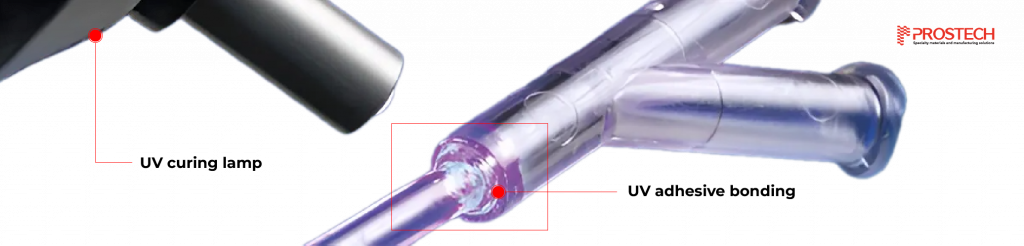

UV adhesive (also known as UV resin or UV activated glue) is a special type of adhesive that cures or hardens when exposed to light of the appropriate wavelength. When polymerization occurs, the UV adhesive becomes hard and creates a strong bond between the surfaces.

To use UV adhesive effectively, a UV light source is necessary to activate the polymerization process. Typically, devices such as UV lamps or UV bulbs are used to provide the necessary UV light.

UV glue comes in various types and brands, each tailored to meet specific needs. Discover Prostech’s available UV adhesive products at:

Benefits of UV Adhesives in Medical Devices Manufacturing

Ultraviolet-curing adhesive are distinguished from traditional adhesive by their superior performance across several key categories including:

- Curing Speed: UV adhesive are known for their rapid curing times. Unlike traditional adhesives that might take hours or even days, UV fast cure adhesives can cure in seconds under UV light exposure. This quick curing feature is especially valuable in fast-paced manufacturing environments like those in the medical device industries.

- Optical Clarity: For applications that require transparency, such as in optical devices and certain diagnostic equipment, UV adhesives provide clear and aesthetically pleasing bonds. This is particularly important for medical devices where visual inspection is necessary

- Biocompatibility: Many UV adhesives have been specially formulated to be safe to use in applications that come into direct contact with the human body, such as surgical tools and implants. This is a critical requirement in medical device manufacturing, where patient safety is the top priority.

- Strong and Durable Bonds: UV adhesives form bonds that are strong and durable, which is vital for medical devices that must endure regular use and sterilization without failing. These adhesives can bond a wide range of materials, including dissimilar substrates, providing flexibility in the design and manufacturing of complex medical devices.

- Low Heat Generation: UV curing generates minimal heat, which is crucial for sensitive components and substrates that might be damaged by higher temperatures. This feature ensures that even the most delicate parts can be bonded safely, maintaining the integrity and functionality of the medical device.

However, businesses are encountering challenges when it comes to maximizing the advantages provided by UV adhesives. Whether you’re seeking guidance on adhesive selection, application techniques, or troubleshooting challenges, our team is here to help. With Prostech’s extensive expertise in adhesive technology, we are equipped to provide comprehensive assistance tailored to your specific requirements. Contact us today to harness the advantages of UV adhesives and elevate your projects to new heights of success.

Applications of UV Adhesive in Medical Industry

UV adhesive is widely used in the medical and healthcare industry due to its ability to cure quickly under ultraviolet (UV) light. Here are some common applications of UV adhesive in the medical field:

-

UV Adhesive for Marking/Decorating Medical Devices

In the medical industry, accurate and durable markings are crucial for the functionality and safety of medical equipment and disposables, such as dialysis machines or test tubes. UV inks and coatings are extensively used for these purposes, allowing for precise and permanent product branding, measurement markings, and the printing of on-demand serial numbers.

UV formulations can be applied through various methods including pad printing, screen printing, and inkjet printing. These methods work effectively on a range of substrates, including paper, glass, plastics, and metals. A notable use of UV marking is on medical patches, bandages, or tapes where logos or other decorative elements are printed to maintain brand visibility and product information integrity.

-

UV Adhesive for Bonding/Assembly Medical Devices

UV adhesives play a pivotal role in the assembly and bonding processes within the medical industry. They are particularly effective for the construction of medical devices like syringes and catheters. With UV curing, medical manufacturers can achieve superior bonding quality at higher speeds and reduced costs.

UV adhesive is also used in optical medical applications, including lenses, microscopes, and other optical medical devices. The structure of UV adhesive in these devices helps secure and protect critical components, ensuring the stability and reliability of the optical system.

-

UV Adhesive for Coatings Medical Devices

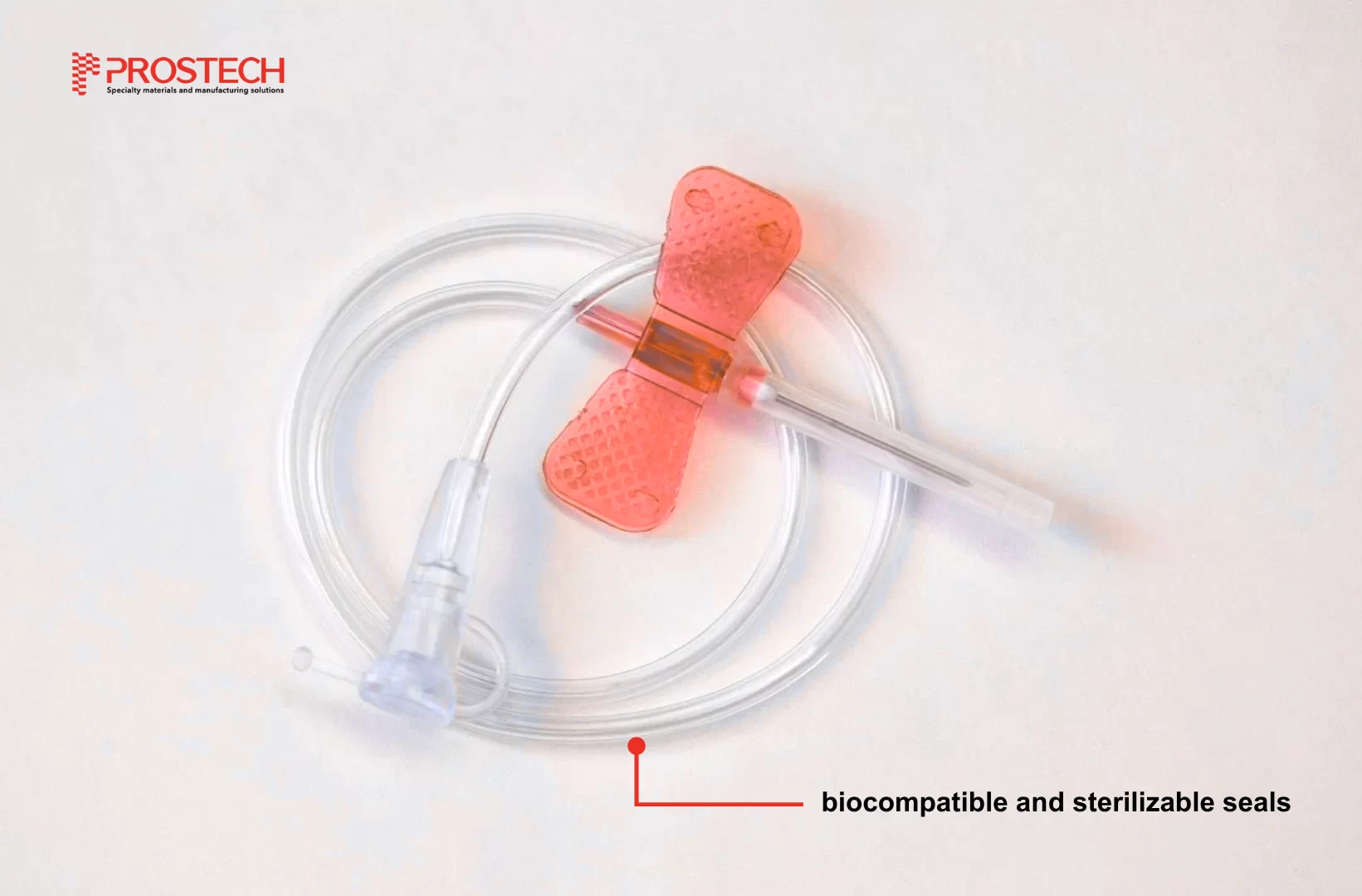

UV coatings in the medical field serve multiple functions, from creating biocompatible and sterilizable seals to applying clear hard coats that enhance durability. These coatings also include functional types that can improve characteristics such as lubricity, which is particularly beneficial in products like catheters and medical filters or promote healing.

Besides UV adhesives, Prostech also offers a myriad of adhesive solutions in the medical industry. From versatile adhesive and tape to advanced sealants, our array of products caters to diverse needs, ensuring precision, reliability, and safety in every application. Discover more at:

UV-cured adhesives mark a significant advancement in both medical manufacturing and maintenance. With ongoing technological progress, UV adhesives are poised to broaden their scope, potentially catalyzing fresh opportunities for innovation in medical device design and construction. However, the process of selecting the appropriate UV adhesive for medical devices entails tackling obstacles such as compatibility with diverse materials, precise curing requisites, and ensuring resilience against environmental conditions and biocompatibility. Should you encounter challenges or seek guidance in effectively selecting and employing UV adhesives, feel free to reach out to Prostech. Our team of experts stands ready to furnish you with the necessary information and consultation to optimize your projects.

[contact-form-7 404 "Not Found"]